Lignin, a formidable foe, has knocked the cellulosic biofuels industry back on its heels, blocking any quick commercial success. But a group of researchers, working within the US government's Great Lakes Bioenergy Research Center (GLBRC) and using the latest bioengineering tools, has created a genetically modified poplar tree (part mutant, all superhero) to save the industry from lignin.

Ultimately, the battle is over the world's tight corn supply. Growing corn on 400,000 farms across the midwest makes the United States, by far, the largest producer in the world, with 32 percent of the world's crop, while exporting 20 percent of it over seas. But 5 billion bushels are diverted into ethanol. Food companies and NGOs have always complained that this makes food more expensive, especially during droughts or other disruptions. Lately, the market has been edgy as events in the Ukraine - the world's third-largest corn exporter - escalate out of control. Everyone, including nervous Iowa corn farmers, is waiting to see if Putin's heavy-handed adventure wreaks havoc on this year's corn harvest.

Unsuccessfully suppressing genes

By now, new cellulosic fuels from corn stover, switchgrass, poplar, and pine were supposed to have been doing some of the heavy-lifting, creating a dynamic duo of sorts, and boosting both the fuel and corn supplies. But the young industry has been battling the usual startup problems, shadowed by its arch nemesis, lignin.

A year ago, less than a month after starting production of poplar-based cellulosic biofuel, ZeaChem failed to get a bridge loan and had to scale back operations, laying off employees. Stumbling along behind are KIOR and Ineos Bio. KIOR's 13 million gal/year Columbus facility produced only 410,000 gallons of fuel during the fourth quarter of 2013. KIOR, which is apparently hovering near bankruptcy, is frantically making improvements. INEOS Bio reported in December that its new facility in Florida also had "startup issues," and the company was busy " de-bottlenecking the plant to achieve full capacity."

In the past, other researchers tried to solve this problem by suppressing genes to reduce the amount of lignin in cell walls. This tended to stunt a tree's growth, making it susceptible to wind, snow, pests, and pathogens.

Researchers in Wisconsin have taken a counterintuitive swipe at the problem: bioengineering poplar trees for weakness (like a quirky, second-tier superhero), which allows them to break down more easily. It's a breakthrough that some reporters have been quick to call a game changer, because it costs less, uses less energy, and creates fewer environmental pollutants.

Bonds easier to break apart

The idea to engineer biomass for "easier degradation" began in the lab of John Ralph, University of Wisconsin-Madison professor and GLBRC plants leader. Ralph was looking to reduce energy costs by more efficiently removing lignin - that reprobate polymer - from poplar trees. Ralph explained other benefits from poplar,"The trees are dense, easy to store, and they flourish on marginal lands not suitable for food crops, making them a non-competing and sustainable source of biofuel."

Ralph eventually reasoned that weak bonds could be introduced into lignin, and this normally hardened material could be "unzipped," making wood much easier to break down. The GLBRC seized the opportunity to try out Ralph's concept and called their far flung experts to help with a range of tasks, from finding the right gene (Curtis Wilkerson, Michigan State University plant biologist), to introducing it into the plants (Shawn Mansfield with the University of British Columbia), and analyzing if the plant was using the new monomers to make lignin (Ralph, University of Wisconsin-Madison).

After Curtis Wilkerson isolated a gene capable of making monomers with bonds that are easier to break apart, he praised the collegial atmosphere: "I guarantee that John Ralph and I would never have met without the GLBRC," then he added, "When I first met him at a group retreat, I knew very little about lignin. But I ended up sharing some techniques I'd been using for totally different projects that I thought might be useful."

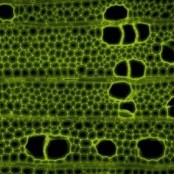

Next, Mansfield put the new gene into the poplars, replacing ether bonds in the lignin backbone with ester bonds that are easier to break down (unzipping), where cinnamoyl-CoA reductase (CCR), an enzyme known to play an important role in lignin biosynthesis, is genetically down-regulated or decreased. "We're designing trees to be processed with less energy and fewer chemicals, and ultimately recovering more wood carbohydrate than is currently possible," says Mansfield.

20 percent higher ethanol production

Finally, before and after the field trials, Ralph determined that the plants not only created the monomers but also incorporated them into the lignin polymer, introducing weak links and transforming the original lignin into a more easily degradable version.

Preliminary data on the group's lignin-modified poplars has been encouraging. "Basic data suggested that the CCR lines' improved performance could be due to structural changes to lignin, in addition to lignin reduction," Ralph said.

Although the extent lignin was suppressed varied between poplars, the study showed that down-regulating CCR resulted in an average of 20 percent higher ethanol production from un-pretreated biomass and, in the strongest cases of suppression, a 160 percent higher yield.

The group's paper, "Improved saccharification and ethanol yield from field-grown transgenic poplar deficient in cinnamoyl-CoA reductase," appeared recently as a cover article in the Proceedings of the National Academy of Sciences.