As chemical engineers consider the economic impact of current and future plant processes, they should evaluate the concept of Techno-Ecological Synergy (TES) for mitigating undesirable outputs from the plant.

Ecosystems services

Natural ecosystems provide humankind with a myriad of economically beneficial services including:

- Provisioning: Minerals, fresh water, biochemicals, biomass, wood fuel and fiber.

- Regulating: Air and water cleansing, climate and flood regulation.

- Cultural: Educational, symbolic, recreational, and spiritual.

- Supporting: Nutrient cycling, primary production and soil formation.

Techno-Ecological Synergy

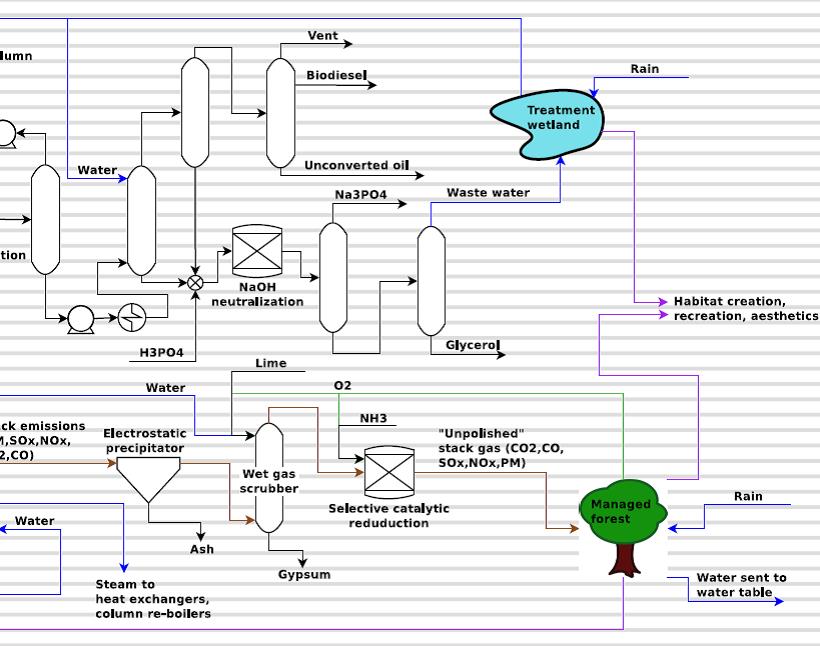

The challenge (i.e., opportunity) presented is to utilize natural ecosystem services in a proactive and designed way to mitigate and support the technological manufacturing and processing operations. This involves thinking "inside the fence" with respect to utilizing natural elements in the overall process flow diagram.

Click to Enlarge

For example, utilization of a wetland on the plant property can greatly reduce the technical requirement of any wastewater and storm water treatment systems, while also providing biomass, CO2 uptake and flow control all within the ecosystem itself. In a similar manner, forested areas on the plant property can help in reducing CO2, NOx and SOx emissions, while providing oxygen, biomass, fuels, and raw materials for the production processes.

A case study

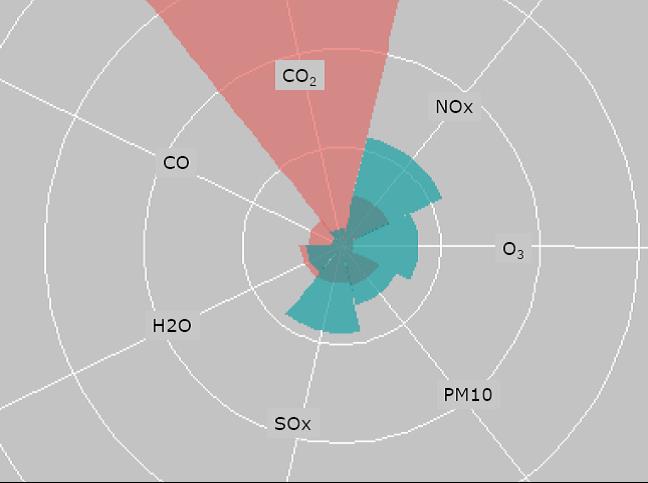

A bio-diesel facility in Cincinnati, OH, was modeled using ChemCAD to assess the positive impact that TES could have on the facility. Like most chemical manufacturing plants, the facility was essentially buildings, tanks, and equipment on an otherwise barren plot of land. In assessing the inputs and outputs of the plant, and the available land and climate, inclusion of a wetland and forest ecosystems on the property were evaluated for their long term ability to "cover" the outputs from the plant including CO2, SOx, NOx, ozone, etc.

Click to Enlarge

On the 23 acre site, 6.54 acres were planted (downwind as much a possible) with silver fir, a local tree species that would provide for the air contaminant process capacity and also would provide biomass and/or fuel to mitigate CO2 emissions. 5.1 acres of the site were designated for overflow wetlands areas, between the plant and the Ohio River. The wetlands provided for additional air contaminants processing capacity along with its primary function for water treatment.

Since forests aren't planted at a mature state, the ability of the ecosystems to "process" the outputs started low and increased over time. In the process simulations at the 20-year mark, the TES approach accounted for at/over 100% ability to deal with the SOx, NOx, ozone and particulate matter effluents from the plant, without any traditional unit operations equipment needed!

Future challenges

Although the TES appraoch is a win-win situation, and the flexibility and sustainability factors are very appealing, there are many challenges to its implementation. Remember that ecosystems are by definition self-designing (vs. imposed), they are under distributed control (vs. centralized) and potentially unpredictable. The task is to harness and utilize these "forces of nature" for the benefit of all.

For more information, contact Dr. Bhavik R. Bakshi at The Ohio State University.