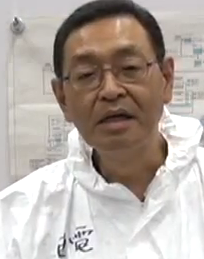

Immediately after the earthquake and tsunami, TEPCO's improvised response was confused and plagued by human error, including the disastrous assumption that an emergency cooling system was working. This dismaying fact - and others - were revealed in an interim report by Yotaro Hatamura, an engineering professor specializing in industrial accidents. After a long investigation, his insights were based on decades of experience (watch class lecture in Japanese, above), all compiled in his Failure Knowledge Database, an exhaustive analysis of over 1,100 industrial accidents. (watch news report or interview withexpert). You can also read the report's translated executive summary. It shouldn't come as a surprise that Hatamura's observations differ strongly from TEPCO's. According to Japan's Mainichi Daily News,

...the remarks contrast with the outcome of an in-house investigation conducted by plant operator Tokyo Electric Power Co., which blamed the larger-than-expected tsunami for the failure to prevent the world's worst nuclear accident since the 1986 Chernobyl disaster.

But few outsiders had any optimism about TEPCO's investigation, which, to be fair, is an observation that can be made about any large, powerful organization trying to examine itself. According to the Wall Street Journal, Mr. Hatamura has said that a major obstacle facing Japanese companies is to own up to their mistakes, examining minor errors and realizing the important lesson before it develops into a grave problem.

TEPCO's flawed corporate culture

The interum report's most damaging observation concerned a philosophy that pervaded TEPCO's corporate culture--acting like a blindfold, or at the very least, an all-purpose rationalization. Hatamura attacked the term "soteigai," or "unforeseen," that plant and government officials had used to describe the scale of the disaster and why they were unable to stop it. He rebuked those officials, saying that running a nuclear power plant inherently required officials to foresee the unforeseen. "There was a lot of talk of soteigai, but that only bred perceptions among the public that officials were shirking their responsibilities," Mr. Hatamura said.

The ultimate result of "soteigai" may have left workers at Fukushima Daiichi untrained and unprepared to handle multiple failures - even lacking the bare necessity of a clear manual to follow. That meant workers at the plant had no accurate sense of real-time events churning and burning within the reactor. And, finally, this may have led to the erroneous assumption that the emergency cooling system was actually working, causing a crucial delay before getting fresh cooling water inside the plant, as molten-hot uranium fuel rods were starting to melt to the containment vessel floor. Hatamura, summed up the 507-page report and concluded:

The Investigation Committee is convinced of the need of a paradigm shift in the basic principles of disaster prevention programs for such a huge system...

The limits of generic simulator training

Granted, some of the most damaging assumptions were made before the earthquake, such as the low tsunami wall. Nonetheless, some in the US nuclear industry say that if Japan had provided US-style training for its operators, they might have performed better during the hectic early moments of multiple meltdowns, and that some of their problems were caused by training Japanese plants operators on generic simulators. John Wheeler, blogger at This Week in Nuclear and nuclear plant training manager, wrote:

The differences between a generic simulator and a plant-specific one are often in precisely the systems the Fukushima operators were struggling with: electrical power supplies, cooling water, and building ventilation...when events stray outside the design basis, include "cascading" failures, and involve severe accident response, generic simulators can't accurately model the events...

Training on generic simulators was abandoned in the US more than 20 years ago, after Three Mile Island. Today, no nuclear plant will be built in the US without a plant specific simulator, and no operator can be granted a reactor operator's license without exhaustive training on that simulator. Wheeler points out another generic simulator flaw: they are often located at a distant location rather than on-site. The result is that operators get far less simulator time per year than operators with access to in-house, plant specific simulators. In the USA, simulator training is deliberately routine and rigorous, with control room operators spending one of every five or six weeks in full-time training consisting of 20 hours at the simulator and 20 hours in the classroom. If a team or individual fails to pass an evaluation, they can't return to the plant until they have retrained and passed a re-evaluation. Read NPR about the training at Grand Gulf Nuclear Generating Station, south of Vicksburg, MS, on the Mississippi River.

The Japanese public copes with TEPCO's mistakes

Wheeler suspects the response to the events at Fukushima will include improvements in operator training. But maybe we should wrap this up with an exasperated editorial from The Japan Times:

With Tokyo Electric Power Co. (TEPCO, operator of the crippled Fukushima plant) in the lead, the sway that Japan's 10 regional electric utilities wield over the politicians, bureaucrats, financiers, academics and captains of the media who together comprise Japan's so-called nuclear village is, in a word, monumental. If there was an Ignoble Prize for Prevarication and Cover-up, last year's would go to Tepco for its repeated, official use of the word s?teigai (meaning, "beyond the realm of predictability") in mitigation of its response to the tsunami that led to the meltdown of three reactors at its Fukushima plant.

Corporate cultures are hard to change - especially one as powerful and entrenched as TEPCO's. It also seems clear that the reported TEPCO mindset, the words and concepts that enable them to rationalize "soteigai," or "unforeseen," effect everyone in the chain of command and, ultimately, the Japanese nation. Unless examined, this (mal)lingering concept could play an off-stage, advisory role in the next tragedy. Masao Yoshida, Fukushima's plant crisis manager and TEPCO's exception to the rule, has been diagnosed with esophageal cancer and recently visited the plant to talk about his illness with workers at the Fukushima plant, fearing media speculation about his health may be affecting the morale of plant workers and their families.