While gas resources are found offshore all over the world, there is an estimated 140 trillion cubic feet of "stranded" gas in Australian waters alone. The offshore Prelude gas field, discovered in 2007 by Shell Oil, has around 3 trillion cubic feet of gas resources. Shell's floating liquid natural gas (LNG) facility will allow these huge fields to be economically developed. 120 crew members will work around the clock to produce 3.5 million tons of LNG each year, plus 1.5 million tons a year of liquefied petroleum gas and other natural gas liquids, resulting in the equivalent of 35,000 barrels of oil per day. The new ship will be built in Korean shipyards. When finished in 2017, it will be towed and then moored about 150 miles off the coast for 25 years of production. "Prelude FLNG will change the rules of the game," Malcolm Brinded, Shell's Executive Director, said in a press release. "It will allow us to access stranded offshore gas fields that otherwise would be too costly or too difficult to develop, because it avoids the need for long underwater pipelines and new coastal infrastructure, which would be written off once the gas played out." The huge ship will chill natural gas produced at the field to -162?C, shrinking its volume by 600 times, so carriers can off load it and then deliver it to Asian customers--particularly energy voracious China and post-Fukushima Japan.

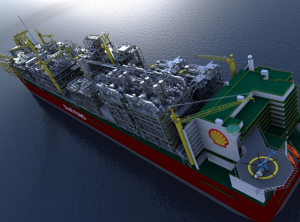

The largest ship in the world

Another plus is that the floating facility will accelerate new developments. This is because the vessel can be ordered at an earlier stage of gas field appraisal, with less guarantee of production longevity than needed for an onshore investment; when the first field is exhausted, the floating facility can be redeployed to another field. Shell's Prelude floating LNG facility will be a maritime monster, and if approached in the fog, it's enormous silhouette would convince even experienced seamen they were seeing a small island. It will be the world's largest floating structure: 488 meters long and more than four football fields end to end. When fully equipped, storage tanks full, it will weigh around 600,000 tons--roughly six times as much as the largest aircraft carrier.

Innovation made the whole project possible

The project's most important innovation: successfully fitting the vessel's technology into an area one quarter of the size of an equivalent onshore LNG plant. The components will stack vertically to save space. The operating plant, for example, will be placed above the LNG storage below deck. The total storage capacity is equivalent to around 175 Olympic swimming pools. To save more space and help cool the gas to -160?C, engineers decided to tap the cold, ocean depths by pumping water into the ship, avoiding the need to for extra equipment on deck. "We've invented a system to take water from deep in the ocean," says Neil Gilmour, Shell General Manager FLNG in a company backgrounder. "It has the potential to change the way we produce natural gas." An assembly of eight one-meter diameter pipes will extend from the facility to about 150m below the ocean's surface. It will deliver around 50,000m3 of cold seawater each hour. The pipes are specially designed to remain stable in strong water currents.

To unload the compressed gas, carriers will have to snuggle up next to the floating LNG facility, towering tens of meters above the waterline. To safely align the FLNG with with each carrier, seawater will be pumped into the double walls of the ship's hull to control its depth. Three 6,700-horsepower engines will sit in the rear, and two of these will run, turning the ship and allowing the LNG carriers to pull safely alongside to load. According to the Petroleum Economist, safety has been a key consideration, beginning with passive protection systems over active ones. The design also includes safety separation gaps between modules. The crew accommodations will be a significant distance from hydrocarbon processing. The FLNG facility is designed to operate and stay safely moored even in the most extreme weather conditions. Its sheer size will help it to withstand very high winds and giant waves. In addition, it will be secured in place by one of the largest mooring systems in the world. A turret will run through the deck of the FLNG facility, with up to 24 mooring lines securing it to the seabed. The system allows the facility to turn slowly in the wind, allowing it to absorb the impact of strong weather conditions while remaining safely moored over the gas field, even during the most powerful cyclones. This will save valuable production days that would be lost disconnecting and moving off the field.

Comments

This is an amazing example of how technology is changing the way we process raw materials and also the way we explore natural resources. Very informative!