AIChE Chemical Engineering for Good Challenge, also known as ACE4G, is a competition to encourage chemical engineering students and their partners to consider how chemical engineering know-how can be appropriately applied on a small scale to improve the quality of life for communities in the developing world.

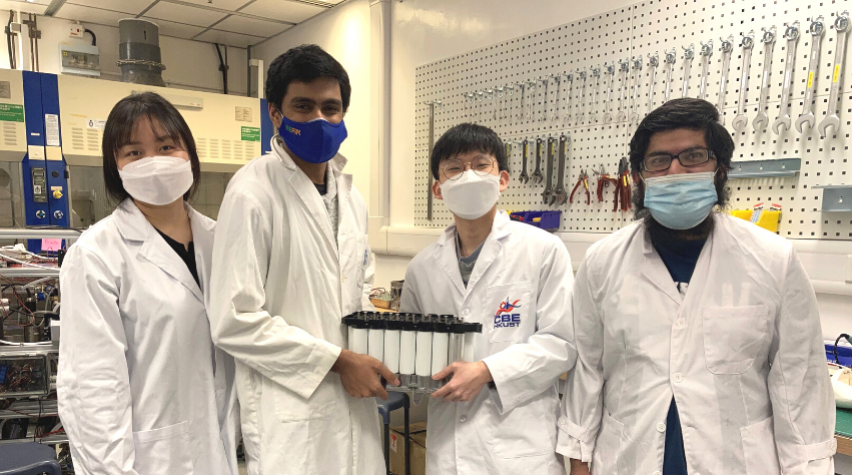

The Hong Kong University of Science and Technology Student Chapter won second place in the competition with their submission “Repurposing Retired Electric Vehicle Batteries for Stationary Use.”

We caught up with the student chapter to learn more about their competition idea, what inspired them to enter the competition, and what they learned in the process.

How did you come up with the idea for your competition submission, “Repurposing Retired Electric Vehicle Batteries for Stationary Use”?

We are a group of final-year students who run a research study in co-operation with CLP Power in Hong Kong regarding battery diagnostics, and finding efficient ways to test batteries for their state-of-health, a term we use to broadly quantify how reusable a battery (that has been cycled a number of times) is. Our on-the-ground research revealed to us that from the “dead” car battery packs we received, over 90% of the battery cells were still in a state of being highly reusable, being able to function at least 90% as well as brand-new battery packs, and only one or two cells dropped below 70% functionality.

Of course, this opens up the possibilities for these packs hugely. Even if they lack the power needed to run a car, they aren’t useless. Hence, we started looking for competitions that might be interested in this finding.

Do you think that the technology you recommended could be implemented on a larger scale?

Naturally. The only real bottleneck in the process right now is finding ways to gauge the performance levels of used battery packs without having to do extensive charge-discharge cycles, which are processes achievable with predictive AI. If such a diagnostic process is perfected, it might be simply a matter of touching a multimeter to an individual cell to get an accurate gauge of a battery cell’s recyclability, accelerating the process from hours to seconds, and opening up industrial-scale applications.

What inspired you to enter this competition?

Though we were initially unconfident in our own work, our professor just told us to give it a shot, and so we did!

What were some of the highlights of working on this competition with your team members? Did you learn anything new in this process?

The greatest highlights of the competition mostly came from being able to see the way my teammates and I solved various issues with the research we were doing, and being able to pull a “rabbit out of a hat.” We all surprised each other with our improvisational skills and pool of abilities that we each didn’t know we had. The most learning was around working with each other and building a team dynamic.