2021 Process Development Symposium

Immiscible Liquid-Liquid droplet dynamics – A CFD model for robust scale-up and risk mitigation

Author

Liquid-liquid systems have a wide range of applications in many fields of the industry. In chemical manufacturing, such liquid immiscibility is most commonly utilized for the purpose of chemical separations by liquid-liquid extraction. Such interphase phenomena depend highly on the droplet size distribution.

The knowledge gained by CFD can be used as a basis for a physics-driven scale-up. The recent years have seen a rapid development of new Graphics Processing Units(GPUs) for computational sciences. We leverage this technical progress with the application of Lattice-Boltzmann (LB) methods which means that we do not longer have to rely on Reynolds Averaged Navier-Stakes equations (RANS).

We begin by performing high resolution direct simulation of two immiscible fluids blending in a lab-scale agitated vessel(Figure 1).

We compare droplet size predictions from this model to first-principles turbulence theory, as well as experimentally measured droplet data. We then use this direct model to simulate the break-up of individual droplets moving through the impeller trailing vortex. From these predictions, we develop a predictive relationship between energy dissipation rates and break-up volume fraction.

We can extract the breakup characteristics of these two-phase immiscible direct simulations and use this knowledge for the design of a model that can be used for larger volumes. The direct simulation provides data on the size and position of the droplets and by detecting step changes in the droplet volume, we can isolate break-up events (Figure 2).

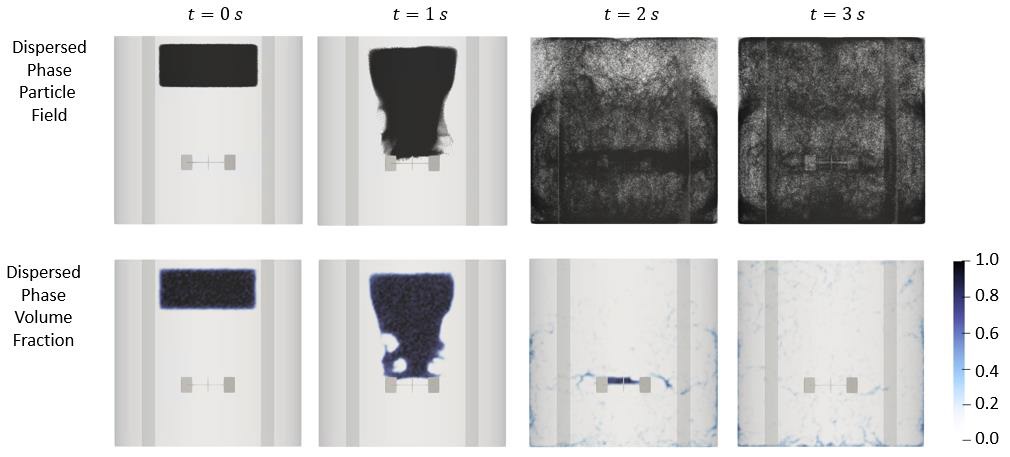

Then, we use a Large Eddy turbulence model (LES) in combination with Lagrangian particles as the dispersed phase to reproduce the droplet size distribution from the direct method with this much faster setup. We are using a hard core-soft shell approach for the particles in this Eulerian/Lagrangian/DEM hybrid model (Figure 3).

This approach allows us to accurately predict droplet size distributions in larger scales in an efficient and fast CFD environment. In order to address full scale production vessels, we use a parcel approach based on the Eulerian/Lagrangian/DEM hybrid model.

All three models predict similar droplet size distribution while each abstraction speeds up the simulation time significantly.