2022 Annual Meeting

(82f) Optimizing the Design and Scale-up of Agitated Filter Dryer

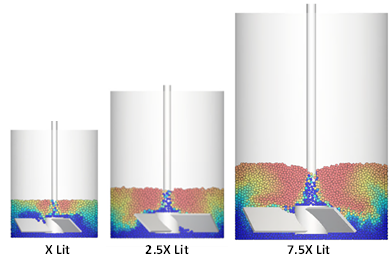

In this study, the Rocky DEM simulation tool is used to evaluate the particle dynamics of wet cake drying in an agitated filter dryer equipment. The impact of operating conditions and geometry configuration on drying is studied to optimize the design and operating space. Beyond that, the influence of various scale-up criteria on solvent drying behavior is also studied when going from a smaller lab scale dryer to a pilot scale dryer. Several important parameters such as type of solvent, particle size, particle shape, and solvent loading can be varied in a DEM simulation. The impact of these parameters on both solvent drying and the particle agglomeration is evaluated and can provide great insights for equipment design and operating conditions, leading to effective optimization of the AFD drying step during the API manufacturing cycle.