2022 Annual Meeting

(676a) Development and Application of a Quick Image Analysis Calibration Procedure for in-Situ Crystal Size Measurement

Authors

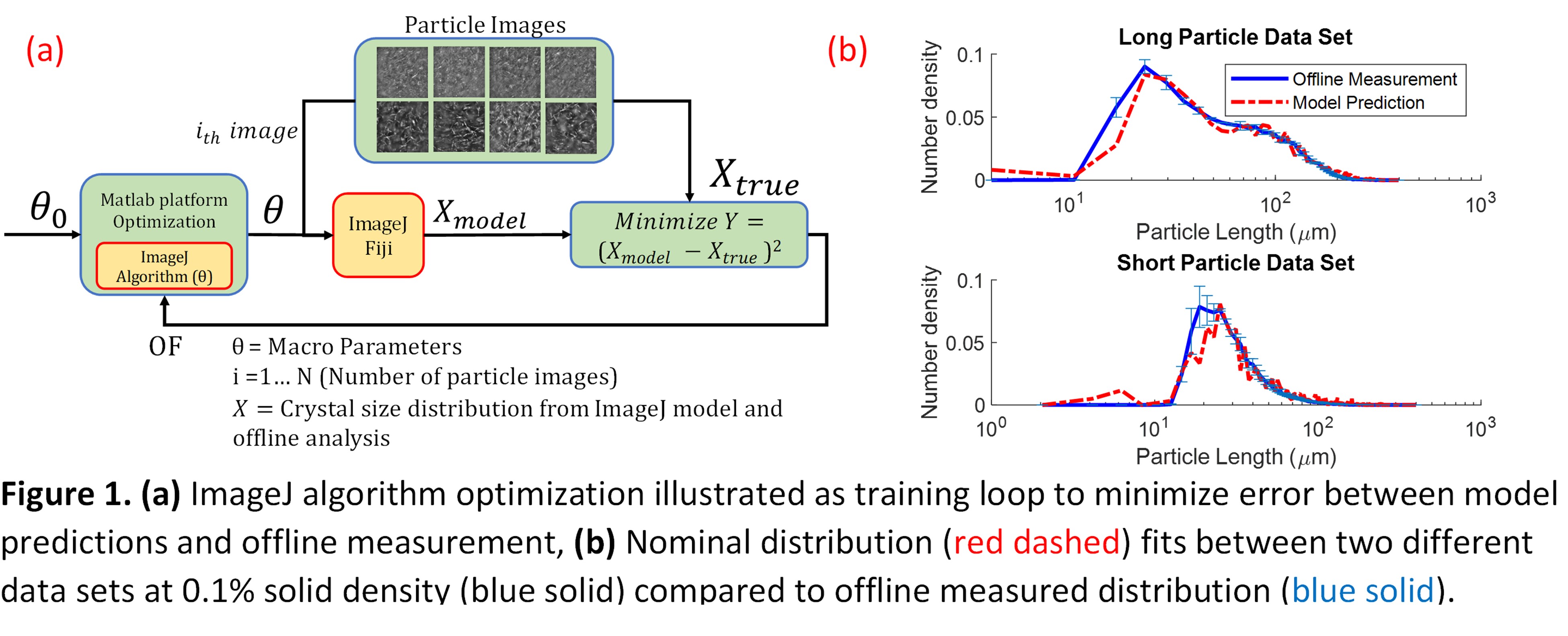

To obtain a fast and accurate in-situ image analysis measurement of particle size for a high aspect ratio nature crystallization system, a systematic off-line image analysis calibration methodology was performed to model offline Malvern Morphologi image analysis results. Grey-scale image analysis algorithms via ImageJ were calibrated to extract size distribution data from in-situ images of varying size and solid density. Different sets of algorithms with varying parameters in the image analysis methods were tested and optimized by minimizing the size distribution error between the model and offline image analysis measurement. Trends observed in the calibrated parameters were then fitted to continuous functions varying in solid density to be able to adapt to changes in solid loading. The algorithms were then validated with a different particle data set with known solid loading for algorithm predictability. Lastly, the usability of the algorithms was tested on a dynamic data set to gauge the processing time and predict the size distribution with varying solid loading throughout the crystallization process due to dissolution, nucleation, and growth.

References:

(1) Acevedo, D.; Wu, W. L.; Yang, X.; Pavurala, N.; Mohammad, A.; OâConnor, T. F. Evaluation of Focused Beam Reflectance Measurement (FBRM) for Monitoring and Predicting the Crystal Size of Carbamazepine in Crystallization Processes. CrystEngComm 2021, 23 (4), 972â985. https://doi.org/10.1039/d0ce01388a.

(2) Larsen, P. A.; Rawlings, J. B.; Ferrier, N. J. An Algorithm for Analyzing Noisy, in Situ Images of High-Aspect-Ratio Crystals to Monitor Particle Size Distribution. Chem. Eng. Sci. 2006, 61 (16), 5236â5248. https://doi.org/10.1016/j.ces.2006.03.035.