2022 Annual Meeting

(66k) Lignin Bioconversion in a Unique Pelletized Cultivation Platform Using Rhodococcus Opacus PD630 Simplifies Biomass Harvesting and Enhances Lipid Production

Authors

Bing Xu, Texas A&M University

Qiang Li, Texas A&M University

Yunqiao Pu, Oak Ridge National Laboratory

Shangxian Xie, Texas A&M University

Arthur Ragauskas, University of Tennessee

Zhi-Hua Liu, Texas A&M University

Joshua Yuan, Texas A&M University

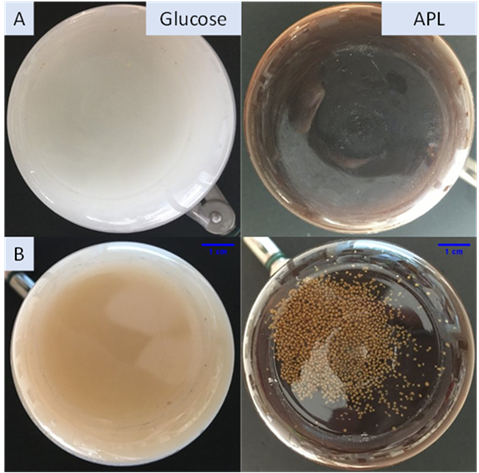

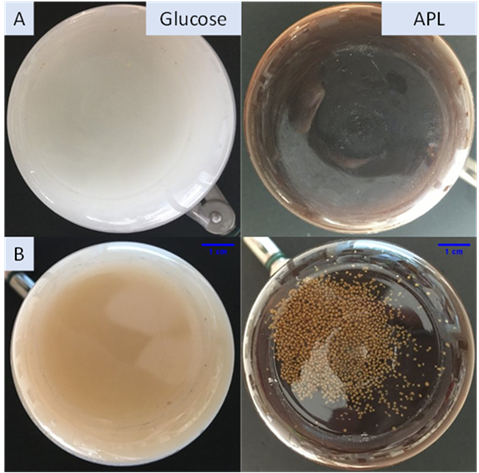

Pelletized liquid cultivation has been widely explored because of its advantages in biomanufacturing, such as easier biomass harvesting, higher product yield, lower medium viscosity and energy consumption. In this study, we discovered that the nonfilamentous bacterium Rhodococcus opacus PD630 could form pellets during the fermentation of alkaline pretreatment liquor (APL) containing lignin as a carbon source. Figure 1 shows pellet formation using APL and no pellet formation with glucose (A=before fermentation, B= after fermentation). This discovery advanced our understanding of bacterium pelletization, as only filamentous fungi and filamentous bacteria were reported to form pellets without the addition of external agents such as flocculants or polymers in previous research. Several factors were investigated to understand how they affect the process of pelletization. Notably, the lipid content in the pellets was much higher than in the scattered bacteria at low nitrogen concentration (<0.5 g/L), under which condition (high carbon to nitrogen ratio) the industrial microbial production for lipids was carried out. Moreover, the highest pellet percentage (â¼60% of the total biomass) was observed at 30 g/L soluble solid content, an agitation rate of 180 rpm, 1.4 g/L NH4NO3, an initial optical density (OD600) of 10, and a centrifugation speed of 6000 rpm. The study opens new avenues to decrease harvesting and cultivation cost as well as energy consumption for microbial fermentation. The physicochemical characteristics of the pellets as well as the chemical changes of the alkaline pretreated liquor after fermentation will be discussed during the talk aiming the elucidation of the pelletization mechanisms.