2022 Annual Meeting

(511f) Detecting Lagrangian Coherent Structures in Twin-Screw Extruder Elements Via Smoothed Particle Hydrodynamics

Authors

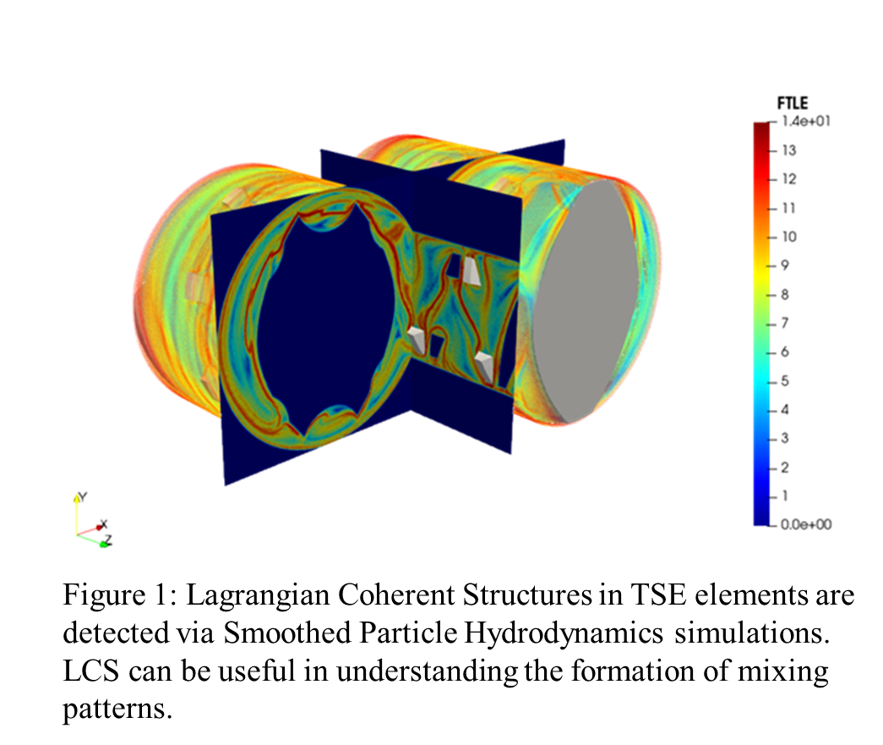

Twin-screw extruders (TSE) are often used to process high viscosity fluids, which are difficult to mix. In the absence of turbulence, the task of creating spatio-temporal disorder (to promote mixing) is achieved with closely intermeshing rotating screw elements. Thus, the geometrical design of these elements is critical for mixing performance. Previous simulation studies have sought to characterize the mixing efficiency via various quantitative measures (i.e., mixing indices). Yet, little is known about the underlying mixing patterns and mechanisms, which hinders improvement of screw designs. Thus, to enhance our understanding, we investigated mixing patterns in TSE elements via Lagrangian Coherent Structures (LCS).

Methodology

Flow simulations were carried out with Smoothed Particle Hydrodynamics1 (SPH). SPH has proven to perform well for predicting the flow in extruder elements.2 The methodâs meshless nature allows for a convenient treatment of rotating moving boundaries such as extruder screws. Additionally, SPH is a Lagrangian method, and as such offers performance advantages for calculating the Finite-Time Lyapunov Exponents (FTLE) fields, which we use for detecting attracting and repelling Lagrangian Coherent Structures (LCS). 3,4

Results

We simulated the flow in three different TSE elements and determined attracting and repelling LCS for each of them (e.g., Figure 1). The LCS reveal the stretching and folding events that cause efficient laminar mixing. Differences between screw element geometries are discussed.

Literature

- J. Monaghan, âSmoothed particle hydrodynamics,â Reports Prog. Phys., vol. 68, no. 8, pp. 1703â1759, Aug. 2005.

- Bauer, H., MatiÄ, J., & Khinast, J. (2021). Characteristic parameters and process maps for fully-filled twin-screw extruder elements. Chemical Engineering Science, 230, 116202.

- Haller, G. (2015). Lagrangian coherent structures. Annual Review of Fluid Mechanics, 47, 137-162.

- Sun, P. N., Colagrossi, A., Marrone, S., & Zhang, A. M. (2016). Detection of Lagrangian Coherent Structures in the SPH framework. Computer Methods in Applied Mechanics and Engineering, 305, 849-868.