2022 Annual Meeting

(493g) Peeling of Linearly Elastic Sheets Using Complex Fluids at Low Reynolds Numbers

Authors

Anirudh Venkatesh - Presenter, Purdue University

Vishal Anand, Davidson School of Chemical Engineering, Purdue University

Vivek Narsimhan, Purdue University

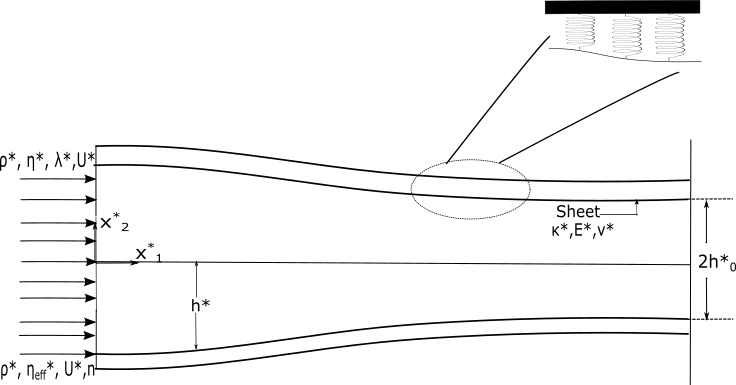

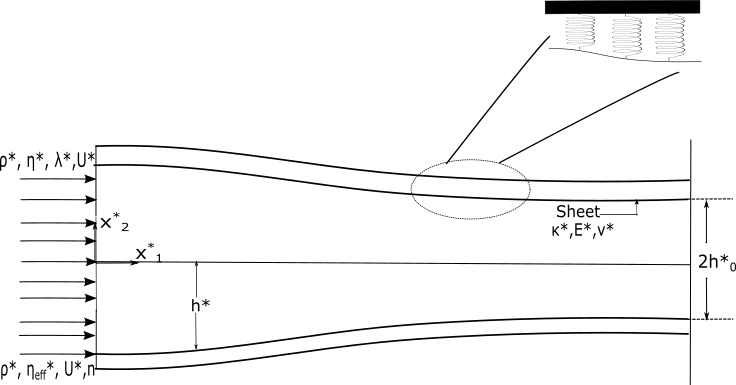

When two elastic sheets are separated by a lubricating layer of fluid, the flow of the fluid can cause the sheets to peel. This situation is common in many applications in nature and industry. In such flows, a slowly moving fluid exerts pressure on the soft(elastic) walls. The deformations, in turn, alter the flow field of the fluid non-trivially. This coupled phenomenon is called fluid-structure interaction (FSI). Moreover, many fluids seen in nature and the industry do not adhere to simple Newtonian rheology. With the advent of microfluidics, it is important for us to get a better understanding of the mechanics behind such complex interactions involving non-Newtonian fluids and deformable structures. We investigate the transient FSI of a non-Newtonian fluid peeling two Hookean sheets at low Reynolds numbers . Two different classes of non-Newtonian fluids are considered â a fluid obeying the simplified Phan-Thien-Tanner (sPTT) constitutive equation, and an inelastic fluid with shear thinning viscosity. In the limit of a small gap between the sheets, we invoke a lubrication approximation and numerically solve for the gap height between the two sheets during the start-up of an inlet pressure-controlled flow. What we observe is that for an impulse pressure applied to the sheet inlet, the peeling front moves diffusively (xf ~ t½) toward the end of the sheet when the fluid is Newtonian. However, when one examines a complex fluid with shear thinning, the propagation front moves sub-diffusively in time (xf ~ t¼), but ultimately reaches the end faster due to an order of magnitude larger prefactor for the propagation speed. We provide scaling analyses and similarity solutions to delineate several regimes of peeling based on the sheet elasticity, flow Weissenberg number (for sPTT fluid), and shear thinning exponent (for generalized Newtonian fluid). These analyses are performed under the specific limits of moderate sheet deformation and strong sheet deformation. In conclusion, this study aims to afford to the experimentalist a system of knowledge to a priori delineate the peeling characteristics of a certain class of complex fluids.