2022 Annual Meeting

(2dl) Elucidating the Mechanical and Transport Properties of Novel Composite Hydrogels Containing Fractionated, Purified Lignin

Authors

While the incorporation of lignin has enhanced mechanical and transport properties in various hydrogel materials, to date, most studies investigating the synthesis of lignin-based hydrogels involve fabrication methods that utilize lignin with high dispersity (Ã) oftentimes greater than 10. Current lignin recovery methods indiscriminately precipitate lignin out of solution, leading to a final product with broad molecular weight (MW) distributions and high metals content (~1â2 wt %, primarily composed of sodium and potassium salts) that poses risk for health and product contamination. As such, the development of lignin-based hydrogels for various applications is hindered by our limited understanding surrounding the role of lignin MW and purity in the formation of the network structure for the resulting hydrogel composite.

Herein, a novel series of ligninâpoly(vinyl alcohol) (PVA) composites were synthesized utilizing ultraclean lignin (UCL) of prescribed MWs applying two different crosslinking agents â methylenebisacrylamide (MBA) and glutaraldehyde (GA). The UCL was acquired through a fractionation process that continuously cleans, fractionates, and solvates lignin with controlled MWs of narrow dispersity and low metals content.

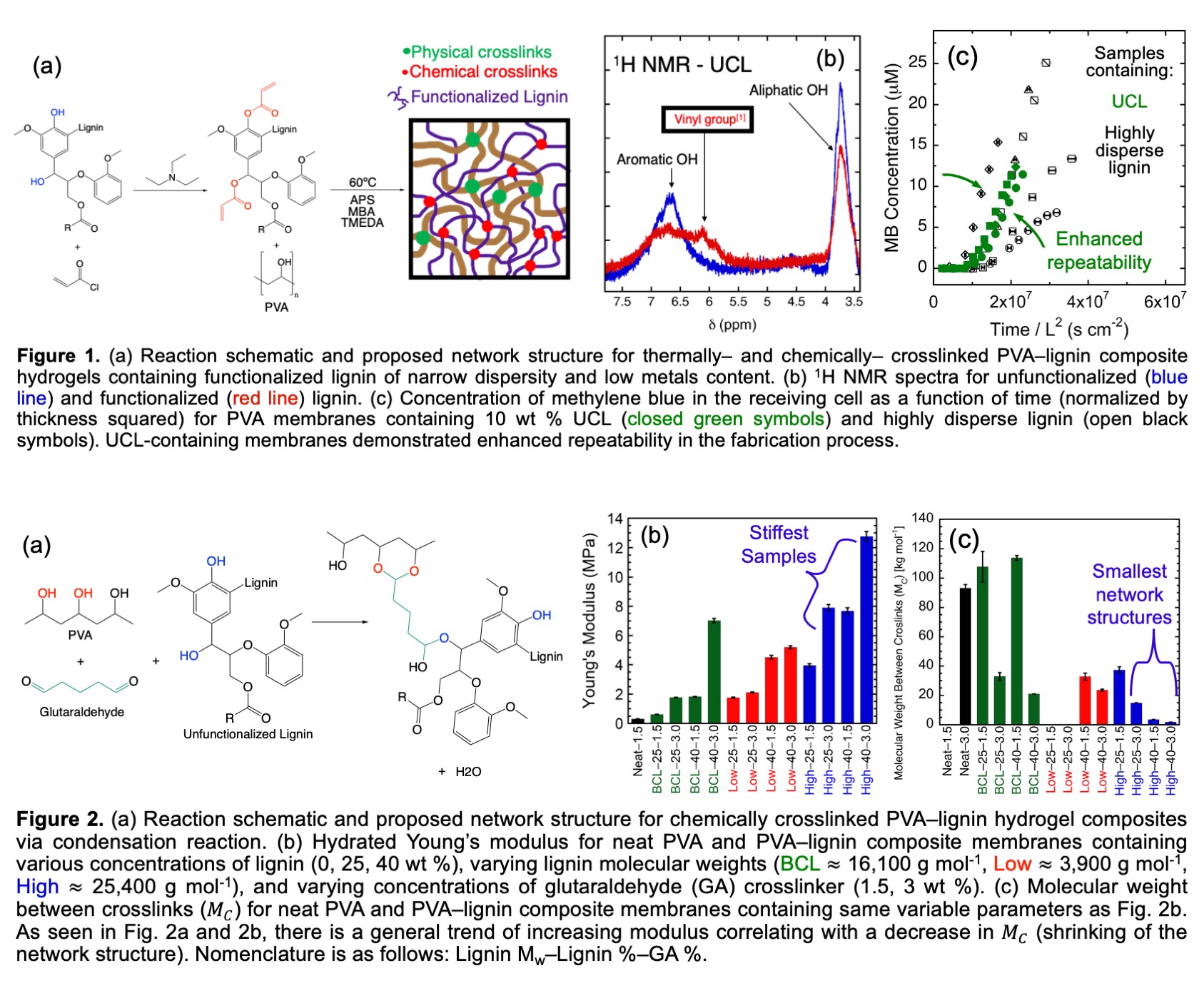

Prior to crosslinking with MBA, lignin hydroxyl groups were functionalized with vinyl groups, allowing lignin chains to chemically crosslink via free radical crosslinking, leaving the PVA chains to thermally crosslink with themselves, creating an interpenetrating network (IPN) as shown in Fig. 1a. Successful lignin functionalization was confirmed via 31P and 1H nuclear magnetic resonance spectroscopy as seen in Fig. 1b where we see the emergence of a vinyl peak at 6.2 ppm. The permeability of methylene blue (MB) through the hydrated composites was measured via ultraviolet-visible spectroscopy (UV-vis), where MB permeability was found to depend on the concentration of lignin in each composite, along with the lignin dispersity prior to fabrication. As seen in Fig. 1c, hydrogel composites containing UCL of narrow dispersity demonstrated a smaller spread in the permeation results as compared to membranes containing highly disperse lignin, underscoring the importance of utilizing well-defined, fractionated lignin of prescribed MWs in these hydrogel composites in acquiring repeatable measurements.

In another synthesis route, crosslinking with GA occurs at hydroxyl groups along PVA and lignin chains via condensation reaction, as shown in Fig. 2a, under both acidic and neutral conditions. The mechanical properties of the hydrogel composites were characterized via ultimate tensile strength testing (UTS), mechanical indentation (to acquire Youngâs modulus), and dynamic mechanical analysis (to acquire storage modulus and molecular weight between crosslinks (MC)). Increases in Youngâs modulus, UTS, and storage modulus were observed with increases in lignin MW, lignin concentration, and GA content prior to fabrication. It was also observed that the stiffest, strongest samples produced the smallest MC values, along with the least amount of water uptake, demonstrating a shrinking of the network structure.

The network structure of the soft composites was further characterized via small-angle neutron scattering (SANS) to get an indirect measurement of the mesh size within the network structure. Scattering data obtained from SANS measurements was modeled using a modified Two Lorentzian power law model to obtain a correlation length for the composite hydrogels. For membranes containing lignin, two correlation lengths were observed in the scattering data. The permeability of various pollutants (e.g., methylene blue, bovine serum albumin) through the hydrated composites was measured via UV-vis, where penetrant permeability was dependent on the MW of both the lignins and PVA, concentration of lignin, and concentration of crosslinking agents utilized during membrane fabrication.

Results from this work underscore the importance of utilizing well-defined, low disperse lignin in the fabrication of next-generation composite hydrogels, as they allow for a direct, systematic approach to elucidating the structure-processing-property relationships in this emerging class of green materials.

Research Interests

My research interests involve polymeric materials, particular hydrogels, for membrane-based separations. Recently, there is a push for utilizing âgreenerâ alternatives to petroleum-based products directly used in fabricating hydrogels. The focus of my research project is incorporating lignin, a âgreenerâ biopolymer, into the hydrogel network structure to lessen the usage of fossil fuels and improve upon mechanical and permselective properties. As such, I have gained expertise in polymer synthesis, various mechanical characterization techniques, transport analysis, and neutron scattering analysis of soft materials. I strive to expand my hydrogel background into more biomedical-based applications, particularly tissue engineering, wound healing, or drug delivery. In my time as a graduate student, I have primarily studied covalently crosslinked hydrogels and aspire to expand that knowledge into physically crosslinked materials that are better suited for swelling and releasing of drugs or proteins, and tissue engineering studies. Additionally, I am interested in strengthening my understanding of other biopolymers suitable in hydrogel applications within the biomedical domain.

Teaching Interests

I have served as a teaching assistant multiple times for the fluid dynamics course offered to undergraduate chemical engineering students at Clemson University. As such, my teaching interests lie in fluid dynamics and graduate-level transport phenomena.