2022 Annual Meeting

(275b) Large Eddy Simulation of a Rotor Stator Spinning Disk Reactor

Authors

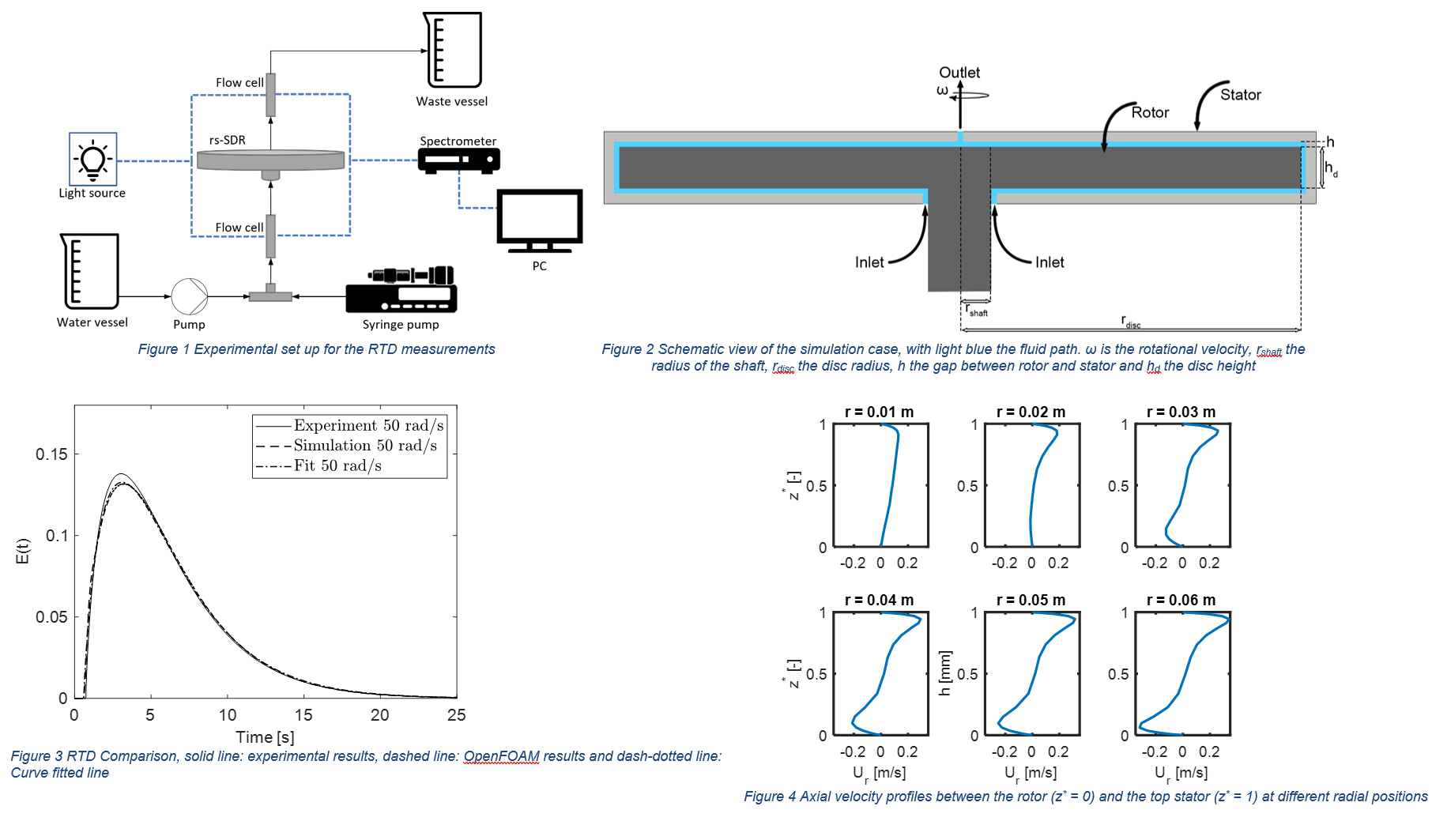

To investigate the flow behavior the following studies have been done; an experimental study on the Residence Time Distribution (RTD) for the rs-SDR and LES of the flow field inside the rs-SDR. The goal of the experimental part is to gain a better understanding of the flow behavior (how to model such system) and to create a validation case for the LES. Therefore a set up was designed and constructed, see Figure 1. The experiments were conducted by using a pump to flow water through the rs-SDR with a flowcell at the inlet and outlet of the reactor. When a stable operation of the rs-SDR was reached, ink was co currently injected via a syringe pump. The spectrometer measured an intensity increase at a certain wavelength at the inlet/outlet and the signal was converted into a concertation profile as function of time, resulting in eventually a RTD curve.

Figure 1 Experimental set up for the RTD measurements

The simulations were done by using OpenFOAM as a Computational Fluid Dynamic (CFD) toolbox. Within OpenFOAM the mesh was created in such way that it represents the fluid flow inside the rs-SDR, see Figure 2. The schematic view represents the rs-SDR from Figure 1 and was resolved by using LES. The model used for these simulations is the Wall Adapting Local Eddy-viscosity (WALE) model, this model simulates the proper asymptotic behavior of the eddy viscosity close to solid walls, while other models use wall damping functions to estimate the behavior near the wall [3]. The computational work was run in two steps; solving the Navier-Stokes equations while having a continuous water flow through the rs-SDR and a separate scalar concentration field while applying a step function to recreate the ink injection. For solving the Navier-Stokes equations about 3*106 iterations were needed and this was done on the Dutch supercomputer Snellius [4]. From the resolved velocity field, the scalar concentration field could be resolved with around 1*106 iterations and this was done on a local desktop. The concentration field was converted into a RTD curve by using Matlab.

Figure 2 Schematic view of the simulation case, with light blue the fluid path. Ï is the rotational velocity, rshaft the radius of the shaft, rdisc the disc radius, h the gap between rotor and stator and hd the disc height

To validate the CFD work in OpenFOAM a comparison between the experimentally and computationally obtained RTDs should be made, see Figure 3. From the analysis all peaks have an area of around one and the peaks between the different cases match well.

Figure 3 RTD Comparison, solid line: experimental results, dashed line: OpenFOAM results and dash-dotted line: Curve fitted line

More analysis will be done on: flow pattern behavior, boundary layer thickness and the entrainment coefficient. The flow behavior of single phase liquid inside the rs-SDR is a combination of a Plug Flow Reactor (PFR) and Continuous Stirred Tank Reactor (CSTR). According to literature the change in regime can be estimated by using a correlation [5], in Figure 4 a clear regime change between r = 0.02 and 0.03 m can be seen. From r = 0.03 m an additional boundary layer starts to form (von Kármán layer) and will result in a more CSTR type of flow behavior. The CFD work will give a better understanding towards the formation of the boundary layers and lead to a better estimation of the flow regimes inside the rs-SDR.

Figure 4 Axial velocity profiles between the rotor (z* = 0) and the top stator (z* = 1) at different radial positions

Next to that the boundary layer thickness and the entrainment coefficient will be compared with the values obtained in literature and will be done in the coming months.

[1] M. Meeuwse, J. van der Schaaf, B. F. M. Kuster, and J. C. Schouten, âGas-liquid mass transfer in a rotor-stator spinning disc reactor,â Chem. Eng. Sci., vol. 65, no. 1, pp. 466â471, 2010, doi: 10.1016/j.ces.2009.06.006.

[2] M. M. de Beer, L. Pezzi Martins Loane, J. T. F. Keurentjes, J. C. Schouten, and J. van der Schaaf, âSingle phase fluid-stator heat transfer in a rotor-stator spinning disc reactor,â Chem. Eng. Sci., vol. 119, pp. 88â98, 2014, doi: 10.1016/j.ces.2014.08.008.

[3] F. Nicoud and F. Ducros, âSubgrid-scale stress modelling based on the square of the velocity,â Flow Meas. Instrum., vol. 62, pp. 183â200, 1999.

[4] âSnellius - SURFsara Knowledge Base - SURFsara Wiki.â [Online]. Available: https://servicedesk.surfsara.nl/wiki/display/WIKI/Snellius.

[5] M. M. de Beer, J. T. F. Keurentjes, J. C. Schouten, and J. Van der Schaaf, âEngineering model for single-phase flow in a multi-stage rotor-stator spinning disc reactor,â Chem. Eng. J., vol. 242, pp. 53â61, 2014, doi: 10.1016/j.cej.2013.12.052.