2022 Annual Meeting

(215d) Mitigating Risks of Feedstock Variability on Low-Temperature Conversion Processes

Authors

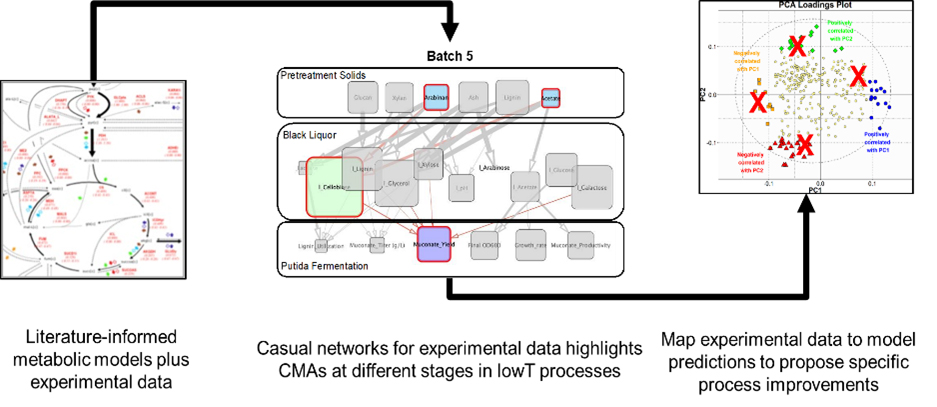

The key learnings from the coordinated, interdisciplinary team highlight how a multi-layered modeling approach (where detailed metabolic models from the literature are linked with powerful machine-learning algorithms â informed by data from carefully designed laboratory experiments) proves to be predictive of the performance of biocatalysts outside of those used initially in the studies. Industry stakeholders will be able to use these models, as well as design guidelines developed using this approach, to inform feedstock selection and bioreactor operation, and therefore de-risk the scale-up of biomanufacturing processes that utilize lignocellulosic feedstocks. Of particular interest to this forum is the observation that multi-layered modeling approaches have uncovered first-principles insights that guide bioprocess optimization. And also the team has distinctly uncovered unique attributes in variable feedstocks that are linked unequivocally to low temperature conversion performance.

Tiered Machine-Learning Networks Will Provide Unique Insights: To enable these findings, the FCIC researchers are leveraging high-quality laboratory data and existing metabolic models to develop an artificial intelligence (AI) framework to predict the effects of feedstock variability on microbial conversion performance. The details of this work will highlight how the approach is well suited to identify the first-principles, metabolic, basis for the impact of feedstock stream attributes on conversion efficiencies â allowing low-temperature approaches to manage feedstock variability. Herein, they have established causal interaction networks to assess CMAs across a diverse set of bioprocesses to understand factors that generally or differentially influence bioconversion efficiency. Combining performance data with metabolic information will result in mechanistic understandings and actionable results, e.g., matching specific biocatalytic agents to feedstocks entering a conversion facility.

Feedstock variability affects bioconversion processes: There are limited public data regarding the impact of feedstock variability on fermentation organism performance using sugar and lignin streams derived from biomass that has been pretreated and deconstructed using deacetylation and mechanical refining (DMR). The FCIC researchers in this study have observed statistically significant changes in deconstruction performance and subsequent biocatalytic productivity and substrate utilization for corn stover feedstocks of varying quality. Strikingly, conversion performance was impacted for both the sugar- and lignin-converting organisms, with different process effects. These results are the first of their kind to determine, in a controlled manner, the effects of feedstock variability on the biological conversion performance of multiple streams derived from diverse corn-stover bales using a variety of biocatalytic processes that produce a range of biofuels and bioproducts. Previously, with limited data, biorefineries would be forced to accept the performance risk of varying feedstocks or invest substantially to generate scientific data and understandings on their unique low temperature process that are not shared publicly.

Valorization of the lignin fraction of cellulosic biomass is critical to biorefinery economic viability, and a key step in many lignin valorization strategies is deconstruction of polymeric lignin to aromatic monomers for biocatalytic conversion or for direct sale. The yields of lignin monomers from base-catalyzed depolymerization (BCD) of residual lignin present after DMR and enzymatic hydrolysis (DMR/EH) varied significantly with the ash and moisture content of several corn stover samples studied. The effects of variability on depolymerization processes need to be understood to optimize this carbon recovery strategy. FCIC researchers found that the variability in the corn stover feedstock resulted in substantial differences in aromatic monomer yields derived from BCD of the residual (post-DMR/EH) lignin, a key step in ensuring economic viability of the overall lignocellulosic-converting process.

Lastly, FCIC research in low-temperature conversion will continue the coordinated modeling and experimental approaches to identify key risks from extended arrays of feedstocks for low-temperature conversion. In addition, the team plans to compare and contrast alternate deconstruction chemistries in addition to DMR (like dilute acid and reactive catalytic fractionation). The team is also well poised to investigate future sources and expanded sets of variability â e.g., that caused by drought stress in the Midwest â in conversion of corn-stover-derived sugar and lignin streams and/or conversion performance of streams enhanced and/or augmented by select components derived from municipal solid waste.