2020 Virtual AIChE Annual Meeting

(716g) Real-Time Optimal Resource Allocation Using Transient Measurements in an Industrial Symbiotic Network

Authors

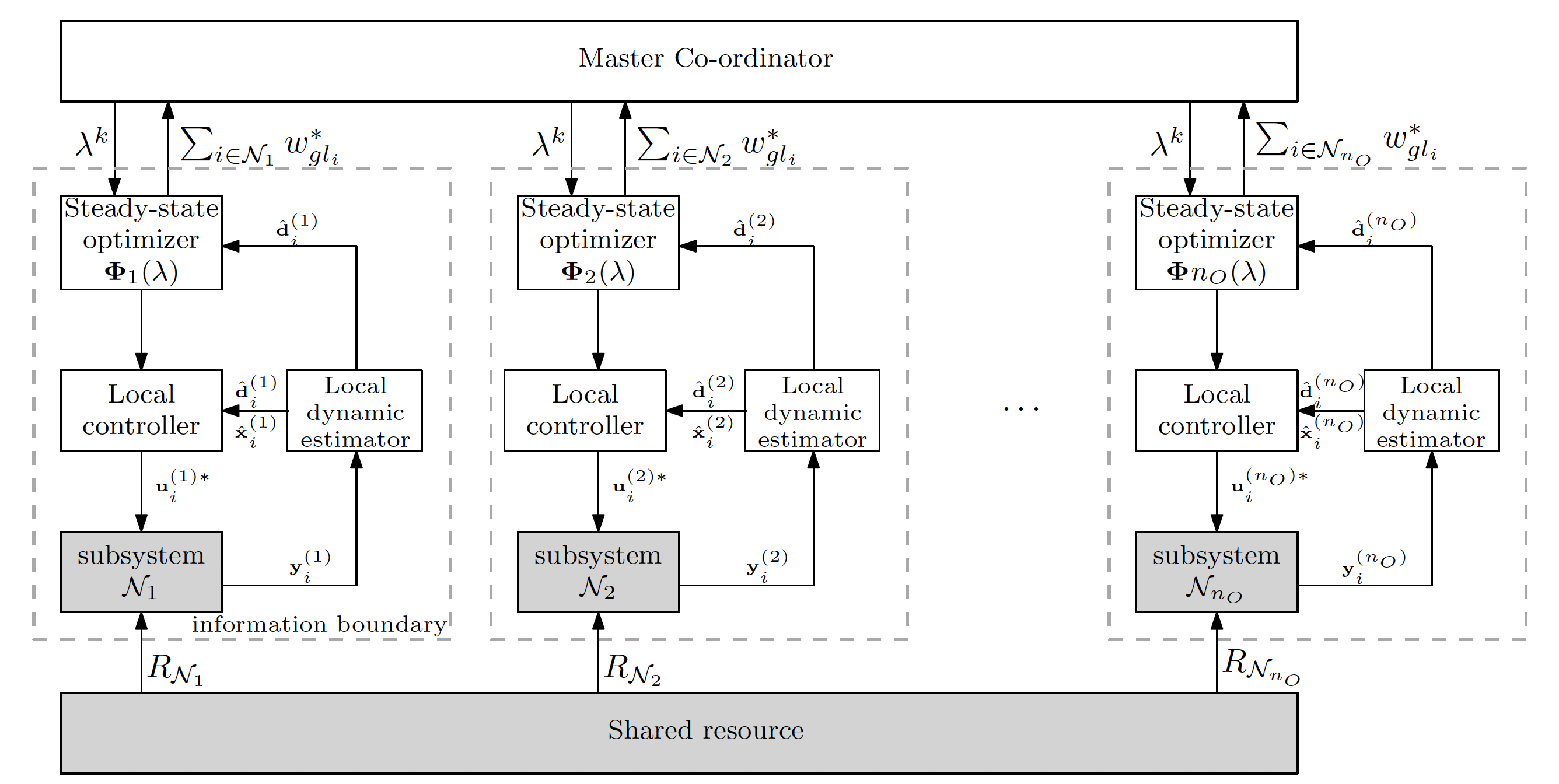

As the process industry is embracing industrial symbiosis, this creates new challenges. For example, optimal process operation in an industrial symbiotic setting requires solving numerical optimization problems using detailed models, which needs to be updated using real-time measurements. This involves sharing information about the process, in the form of models, real time measurements, local constraints and the economic objective across the different organizations involved in the industrial symbiosis. This may not be desirable due to several reasons such as intellectual property rights, trade secrets and market competitiveness. One potential solution that facilitates such industrial symbiosis is the distributed optimization framework, where the different subsystems are locally modelled and optimized. The subproblems report only limited information, such as the shadow prices and the shared resource consumption to a master coordinator, which then co-ordinates the different subsystems in order to achieve overall optimal operation of the network. This way, the different operators avoid the need for sharing the detailed models, real-time measurements and local constraints with one another, in addition to some other benefits, see for example [2] and the references therein

However, a fundamental limiting factor when solving a steady state real-time optimization, is the steady-state wait time associated with the online model adaptation. The RTO routine must wait until all the subsystem reach steady-state, before the model can be updated and re-optimized. This results in suboptimal operation during transients because we discard large chunks of transient measurement data. This is especially challenging in the case of distributed optimization due to differences in process dynamics, disturbances etc between the different subsystems. Simply put, the steady-state wait time is determined by the last subsystem that reaches steady-state. To address the steady-state wait time issue, we recently proposed a hybrid RTO approach, where we update the model using dynamic models and transient measurements [2].

In this talk, we extend the hybrid RTO framework to the case of distributed optimization, where each of the subsystems are updated independently using dynamic models and transient measurements and the steady-state distributed optimization problem is solved using alternating directions method of multipliers (ADMM). The proposed distributed hybrid RTO framework using transient measurements is demonstrated using a subsea oil and gas production optimization problem, with shared resources among different companies.

References:

[1] Wenzel, S., Riedl, F. and Engell, S., 2020. An efficient hierarchical market-like coordination algorithm for coupled production systems based on quadratic approximation. Computers & Chemical Engineering, 134, p.106704

[2] Krishnamoorthy, D., Foss, B. and Skogestad, S., 2018. Steady-state real-time optimization using transient measurements. Computers & Chemical Engineering, 115, pp.34-45.