2020 Virtual AIChE Annual Meeting

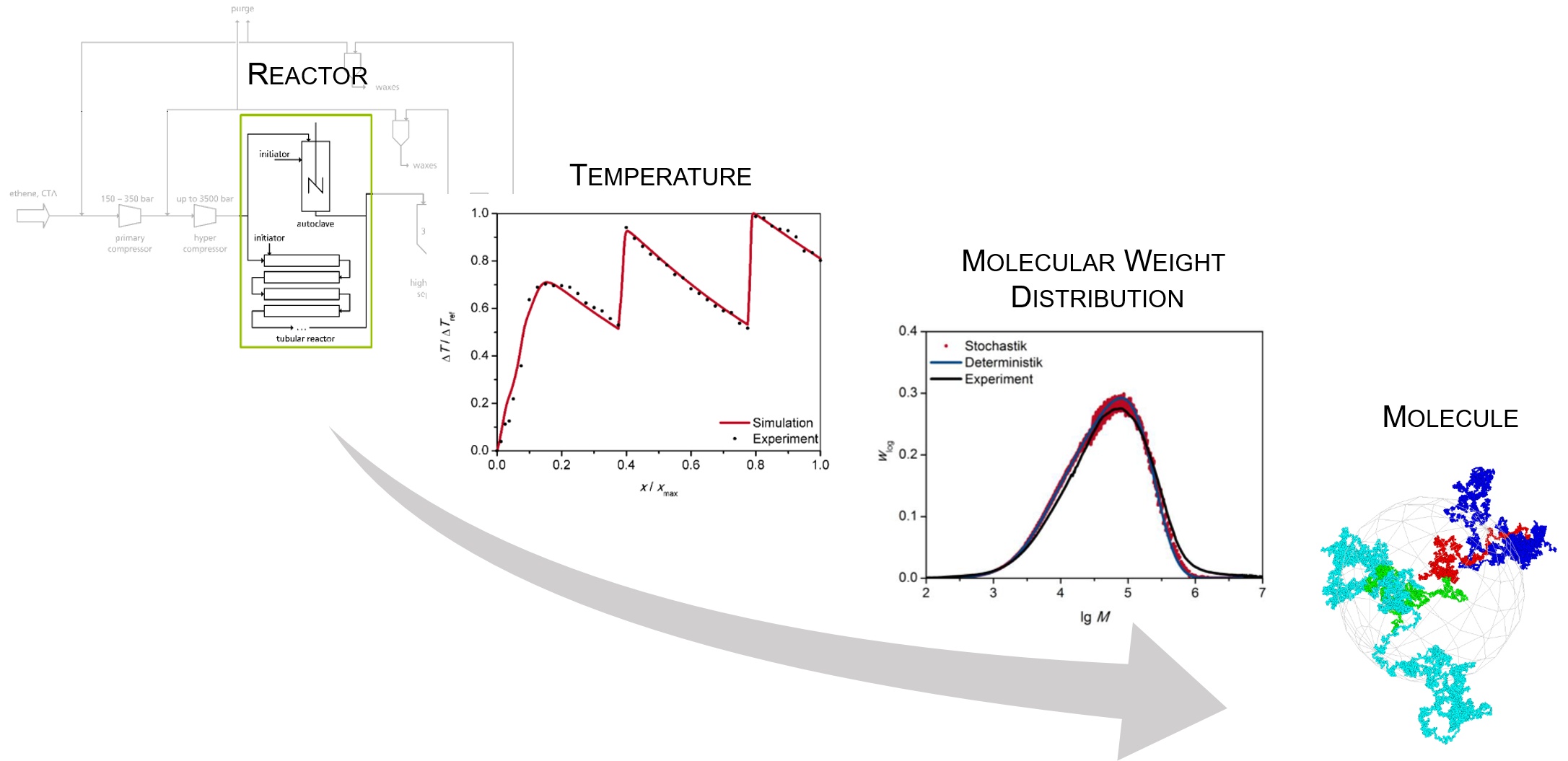

(649a) From Process to Structure – Material Development on Ldpe World-Scale Plants

Author

It will be demonstrated how from fundamentals such as independent kinetic experiments on laboratory scale, detailed analytics of the polymeric micro-structure and engineering knowledge simulation models can be built to describe the control of polymeric micro-structure by process conditions. Transferring the micro-structure into models of rheology bridge to application properties. It is important to validate such concepts on well-defined experiments what will be demonstrated at hand of well-defined mini-plant experiments. The scalability capabilities will be demonstrated applying the identical concept to state-of-the-art reactor technology on production scale. In the same manner it will be demonstrated how data for safety assessment can be evaluated on laboratory scale and then transferred to industrial application. As ethene under high-pressure process conditions has no upper decomposition limit this is valuable to explore the maximum operation conditions on industrial scale.

Using such examples, it will be discussed how detailed knowledge from fundamental investigations on laboratory scale can be transferred into industrial application. This is an essential advantage in speeding up developments and implementation for new processes and materials.

As time permits aspects of process safety will be discussed. Ethene has no upper decomposition limit under such process conditions and with this, deflagrations are a potential risk when driving the process too aggressive. For prevention detailed knowledge about the ignition and propagation of such deflagrations is indispensable. New aspects come into focus by recent demands on circularity and it is necessary to inspect where the potential in future developments is for this field.