2020 Virtual AIChE Annual Meeting

(604e) Optimal Design of Water Distribution Networks to Reduce Freshwater Consumption in Shale Gas Fields

Authors

One of the major concerns regarding shale gas development is water management. A single well typically requires 5 million gallons of water to be fractured, and up to 30% of the injected water may come out of the well as flowback water in the first days of production, after the well is completed. Mainly due to its high salinity, the impaired water poses difficult challenges for shale gas producers. One possibility is to treat the impaired water in centralized treatment plants (Yang et al., 2014), what has been proved to be impractical so far. Nowadays, the more sustainable option is recycling. Many studies suggest that it is possible to successfully fracture a well using all recycled water (Blauch, 2010). Operators are increasingly reusing the flowback water to reduce the freshwater consumption for fracturing new wells (Drouven and Grossmann, 2017), while impaired water disposal expenses can also be lowered. There are two basic strategies: (a) recycling water on-site, feeding it back to impaired water storage tanks for future fracturing operations (intra-pad recycling), or (b) sending the impaired water to neighboring pads and reusing it in upcoming jobs (inter-pad recycling). Direct reuse of flowback water has been possible due to the development of salt-tolerant friction reducers, and is currently the most popular option due to the operational simplicity for contractors. In fact, roughly 90% of the flowback water is being recycled in the development of the Marcellus shale (Sun et al., 2019).

However, shipping costs are a major consideration in recycling. Companies tend to recycle water using a system of storage ponds. They are specially built for water from fracturing, with double liners and leak control alarms. The economics of water reuse remains an issue in many places, based on the fact that it is costly to haul millions of gallons of water using trucks. Recycling in Pennsylvania, for instance, is likely the lowest cost alternative where there are ponds built for storage and treatment near the drill sites (Rassenfoss, 2011). As a result, it is not surprising that, where possible, the companies install water pipes to connect the wellpads among themselves. This appears to be the leading option in the development of shale gas resources in Argentina, for instance, where the main productive region (the Vaca Muerta formation) is over a semi-desert landscape, yielding less expensive pipeline installation costs. In spite of high investment costs, there are currently over 30,000 miles of pipeline either under construction or planned in North America. This suggests that, despite their high upfront costs, pipelines are considered a worthwhile investment. Pipelines also require much less human capital than the other modes, and are more efficient, reliable and safe. On average, transporting products by pipeline costs about $5 per barrel compared to $10-$15 a barrel for rail and $20 a barrel by truck (Congressional Research Service, 2014).

In US shales, the network of water pipelines is growing fast, but the main question is how to plan new expansions. Recent works address the water management problem together with the fracturing schedule (Yang et al., 2015; Drouven & Grossmann, 2017; Carrero-Parreño et al., 2018). However, since the number of fracturing crews and wellpads being considered are too small, the chance to take advantage of pipelines moving water from one pad to the other is not clear. Some of these works account for only one crew, and it is not possible to return to the same pad to stimulate more wells, what makes the problem less attractive from the water flow planning perspective. In turn, Drouven and Grossmann (2017) solve a problem with up to two fracturing crews over four candidate wellpads, allowing for return-to-pad operations. However, all water hauling is assumed to be made by truck. Furthermore, equipment mobilization costs are not included in the model. The mobilization issue is later addressed in detail by Ondeck et al. (2019) in the multi-operational development planning of wellpads, but the model complexity is too high to be extended to more than a single pad, thus being unable to tackle inter-pad water transportation challenges.

The current work is aimed at addressing the integrated planning of shale gas operations in multiple wellpads together with the design of water pipeline networks to maximize water recycling. The optimization model permits to thoroughly solve the challenging return-to-pad trade-off, yielding cost-efficient and well-balanced schedules, both from gas production and water consumption points of view. Compared to previous approaches, the main contributions of this work are the following:

(a) We propose a novel approach based on the concept of campaigns for scheduling shale gas development operations at a very detailed level. The model tightness enables us to solve larger instances of the problem, involving a significantly higher number of resources (rigs, crews, equipment, etc.), wellpads and wells.

(b) Based on the model efficiency, we are encouraged to integrate the multi-pad development planning with the optimal design of water pipeline networks and storage facilities, to maximize the reuse of impaired water coming from fractured wells.

(c) We are also able to solve the problem under uncertain conditions, making it possible to build a robust water pipeline network structure. Uncertainty is mainly associated with land permits issuing dates, and is captured by a two-stage stochastic programming approach.

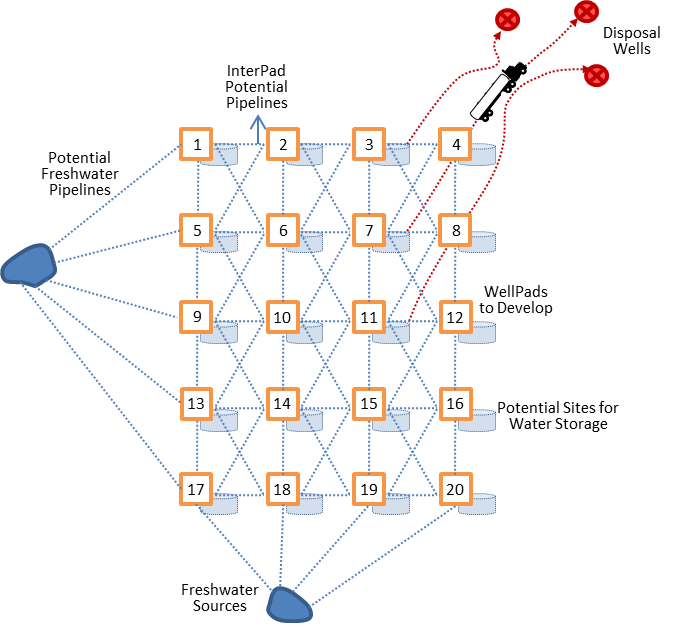

As first-stage, here-and-now decisions, the optimization model is aimed at determining an efficient and robust water pipeline network, accounting for the size and location of inter-pad segments (moving fresh or impaired water on either direction) and the size and location of water storage facilities, where impaired water is temporarily stored before recycling. For the second-stage decisions, the model optimally determines the time to perform the operations for the development of new wells at every pad, and the amount of water to move from freshwater sources to pads, from pads to other pads, from pads to storage facilities, from storage facilities to pads, and eventually from storage facilities to disposal wells; at every period of the time horizon.

Results on an illustrative example involving 20 pads, 4 fracturing crews, and more than 100 wells show that the design of water pipeline networks for shale gas development can be certainly optimized. The use of pipelines to move water between pads in either direction makes it possible to take more advantage of return-to-pad operations, although impaired water transportation should be carefully coordinated with fracturing tasks to avoid overloading and running out conditions. Overall, the optimal pipeline infrastructure permits to minimize freshwater consumption, save on transportation costs, reduce the risk of leaks and environmental impacts, increase water supply reliability, and avoid the need for water disposal after one year of operation.

References

M.E. Blauch (2010). SPE Unconventional Gas Conference, 23-25 February, Pittsburgh, Pennsylvania, USA. doi:10.2118/131784-MS

Congressional Research Service. (2014). US Rail Transportation of Crude Oil: Background and Issues for Congress.

A. Carrero-Parreño, J.A. Reyes-Labarta, R. Salcedo-DÃaz, R. Ruiz-Femenia, V.C. Onishi, J.A. Caballero, I.E. Grossmann (2018) Ind. Eng. Chem. Res., 57:13131-13143.

M.G. Drouven, I.E. Grossmann (2017) Journal of Petroleum Science and Engineering,

156: 983-995.

C. Nunes, Can Natural Gas Be a Bridge to Clean Energy? National Geographic, Jan 10, 2020.

S. Rassenfoss (2011). Journal of Petroleum Technology, 63:48â51.

Y. Sun, D. Wang, D.C.W. Tsang, L. Wang, Y.S. Ok, Y. Feng (2019). Environment International, 125:452-469.

US Energy Information Agency. Annual Energy Outlook 2020.

L. Yang, I.E. Grossmann, J. Manno (2014). AIChE J., 60: 3490-3501.

L. Yang, I.E. Grossmann, M.S. Mauter, R.M. Dilmore (2015). AIChE J., 61: 1770-1782.