2020 Virtual AIChE Annual Meeting

(593f) Phosphide Formation Under Reductive High Temperature Process Conditions during Basic Oxygen Furnace Slag Treatment

Authors

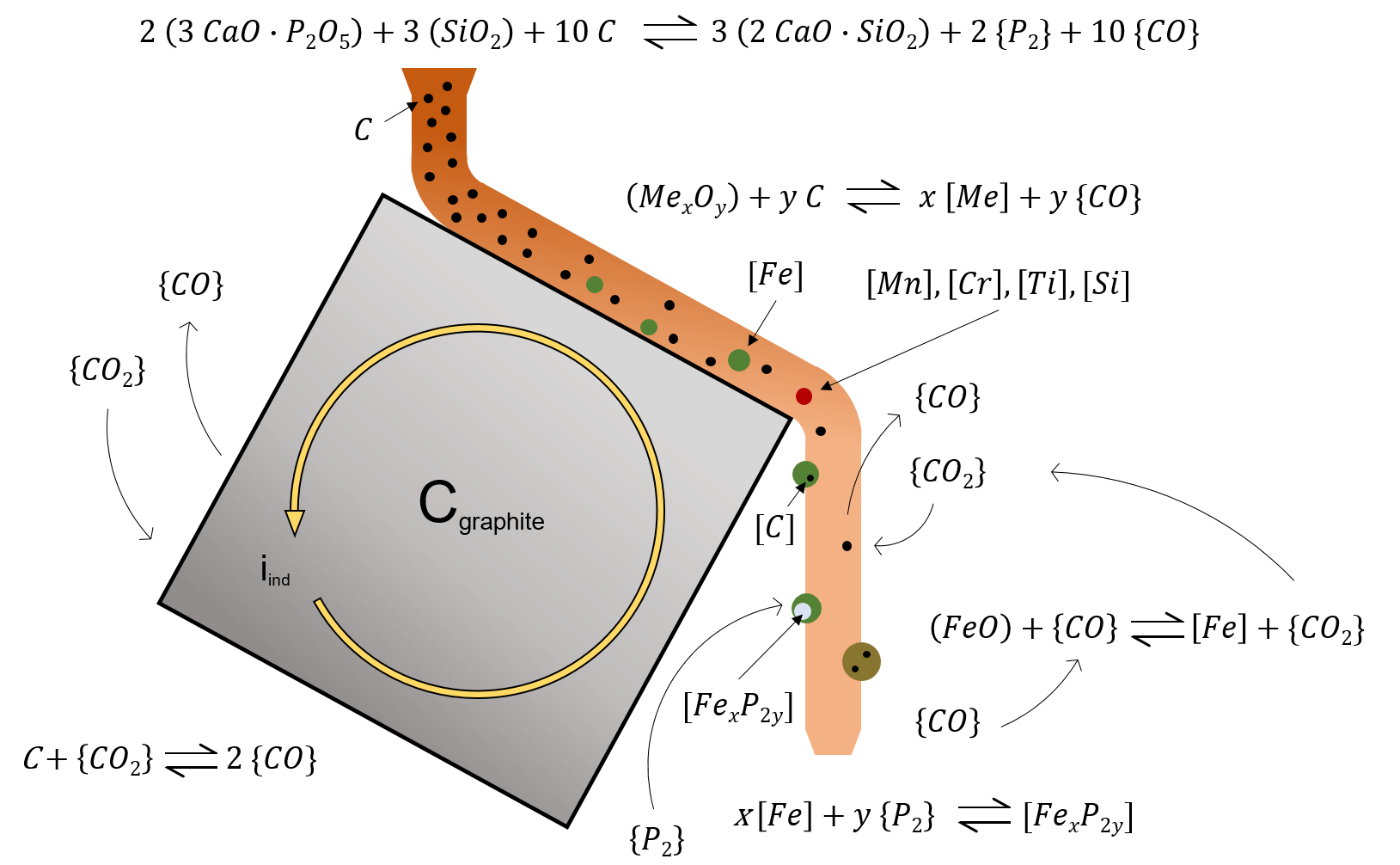

In previous publications the authors present a novel reactor concept that enables the gaseous removal of phosphorus during the full reduction of BOFS. In this so-called InduRed reactor, a bed of graphite cubes is inductively heated. The advantages of a packed bed column â namely its large surface area and the formation of a liquid film providing short mass transport distances â for the transfer of reduced phosphorus from the liquid phases (iron alloy and slag) into the gas phase are introduced to high temperature process engineering. In addition to the direct heat input by induction, the product gas (mainly CO and P2) is constantly removed from the reactor. While a removal of phosphorus to an extent of 85% was achieved with modified BOFS (addition of SiO2 in a prior smelting step), the presence of iron and the formation of iron phosphides are assumed to inhibit the gaseous removal of the remaining 15%. Furthermore, the product slag from this process is virtually iron-, phosphorus- and chromium-free.

Current research at the Chair of Thermal Processing Technology of the Montanuniversitaet Leoben has theoretically investigated the feasibility of an alternative BOFS treatment process. In it, the slags are to be fully reduced in a well-established aggregate such as an electric arc furnace. Phosphorus will be almost completely accumulated in the iron alloy produced. This alloy, however, shall subsequently be converted with additives so that the production of a chromium- and phosphorus-rich slag is facilitated that is as low in iron oxide as possible. Due to its reaction behaviour, manganese will presumably also be oxidised to a great extent. Such slags have been theoretically anticipated and produced synthetically, because they are not yet produced on an industrial level. The reduction occurred in the InduRed reactor mentioned above. While it was expected that the phosphorus removal via the gas phase should work better with low-iron slags, phosphorus gasification results were worse â roughly 45% gasification â than the ones obtained from modified BOFS.

The research presented in this publication deals with the formation of phosphides with chromium and manganese, which are expected to have led to these results. Respective literature does not provide enough data to thermodynamically assess the formation of iron, manganese and chromium phosphide formation, neither separately nor combined.

Meanwhile, the anticipated slags from the second converting step mentioned before have already been produced in experiments on a semi-industrial scale. Such slags will be reduced in the proposed reactor and the results presented above shall be verified by increasing the number of experiments. The results will be assessed in this publication.