2020 Virtual AIChE Annual Meeting

(391e) Evolution and Interaction Characteristics of Liquid Flow and Bubbles in a Jet Bubbling Column

Authors

The evolution and interaction characteristics of liquid flow and bubbles in a jet bubbling column are numerically studied through a Computational Fluid Dynamic-Population Balance Model (CFD-PBM) coupling method. The axial velocity distribution of liquid velocity at different heights in the column is measured experimentally and compared with the simulation results to verify the accuracy of the CFD-PBM coupling model.

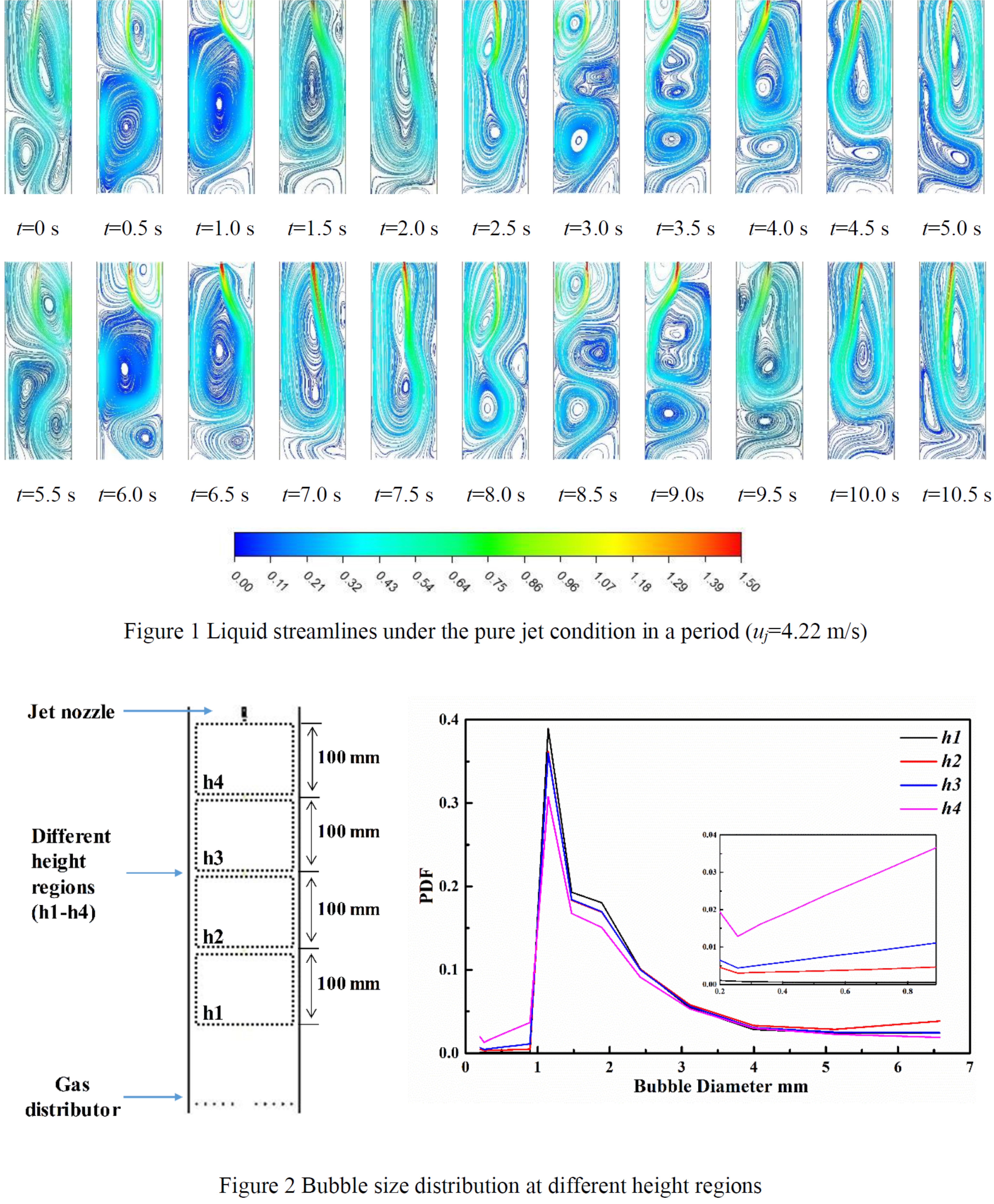

Simulation results show that the flow field in the column varies periodically. The period under the jet bubbling condition is longer than that under the pure jet condition. As shown in Figure 1, during a period, the liquid vortices continuously entrain and release bubbles, which can be observed experimentally. The liquid has both transporting and breaking effects on bubbles. On the one hand, the liquid vortices that move periodically transport the bubbles to various regions of the column, which is beneficial to the gas-liquid effective mixing in the column; on the other hand, the strong turbulence at the exit of the jet nozzle promotes the breakup of the bubbles. As the height increases, the proportion of bubbles with a diameter of smaller than 1 mm gradually increases, and the proportion of bubbles with a diameter of larger than 1 mm gradually decreases, as shown in Figure 2. The main region for bubble breakup is between the exit of the jet nozzle and 100 mm below it. We have proven that the CFD-PBM coupling model employed can be used to simulate the flow field of a jet bubbling column, which is of great significance for the industrial application and optimization of the jet bubbling column reactors.