2020 Virtual AIChE Annual Meeting

(343h) Highly Permeable Supported PDMS Ultrathin Films As a Gutter Layer for Gas Separation Composite Membranes

Authors

Lingxiang Zhu - Presenter, National Energy Technology Laboratory

Victor A. Kusuma, Leidos Research Support Team

David Hopkinson, NETL

Kevin P. Resnik, Leidos Research Support Team - US DOE/NETL

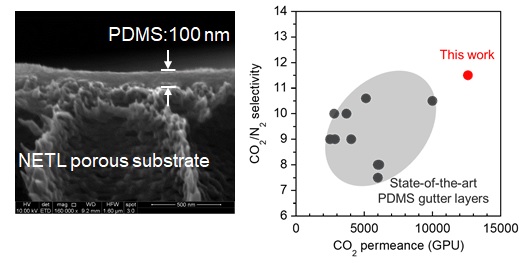

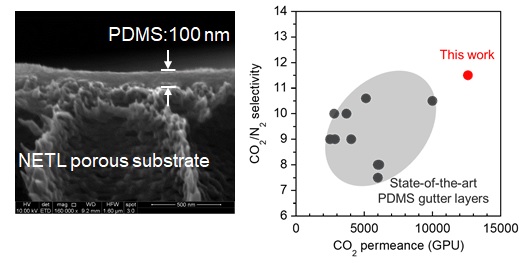

Zi Tong, The Ohio State University

Engineering useful membrane materials into ultrathin selective layers is the key to maximize membrane gas permeance for energy-efficient separations. The fabrication of a defect-free ultrathin selective layer usually requires a porous substrate to provide mechanical strength and a gutter layer to offer smooth coating surface and prevent pore penetration, forming a multilayer thin film composite (TFC) membrane. Polydimethylsiloxane (PDMS) is the most commonly used gutter layer material due to its high permeability and non-aging property. To minimize gas transport resistance introduced, the supported gutter layer should be 10-fold or more as permeable as the thin selective layer. However, current PDMS gutter layers can hardly provide more than 10,000 GPU CO2 permeance, which are insufficient to support high-permeance TFC membranes, especially those for CO2 capture from flue gas. The low permeance is most likely caused by the PDMS material intrusion into the porous substrate with limited porosity. To address this issue, we report a supported 100 nm-thick PDMS gutter layer with a record CO2 permeance of 12,600 GPU and CO2/N2 selectivity of 11.5 at 25 °C. This extremely permeable yet defect-free gutter layer was achieved on a high-porosity (~20%), nanoporous (pore diameter of ~40 nm), and chemical-resistant polymer substrate that was developed through a traditional phase-inversion method. This presentation will discuss the formation of the high-performance porous substrate as well as the subsequent fabrication of the ultrathin PDMS gutter layer with minimal material intrusion. The sought-after performance and good scalability make this supported PDMS thin film a promising gutter layer for high-performance and large-scale TFC membranes for gas separation.