2020 Virtual AIChE Annual Meeting

(320b) A Multi-Level Coarse Graining Technique for Discrete Element Method (DEM) Simulation

Authors

AlthoughSakai and Koshizukatype coarse graining has been demonstrated successfully for many systems, the accuracy is good only until the diameter ratio between the coarse grain particle to the original particle is about two. If the coarse graining ratio is increased to a higher value, the accuracy of the simulation reduces substantially even for a simple hopper discharge problem. Beyond a certain threshold, the simulation artefacts become dominant at certain parts of the equipment. One such artefacts is choking in hopper flow.

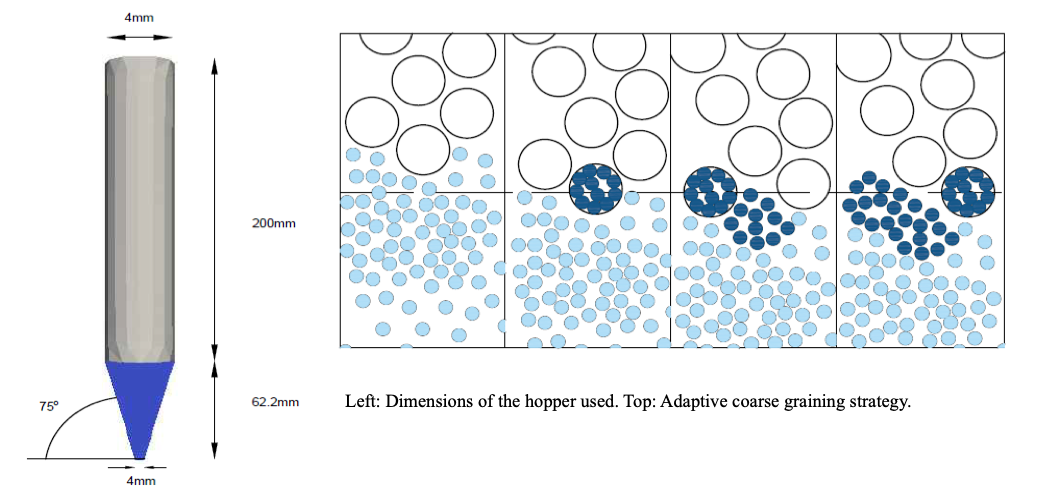

In this work we demonstrate a new method which resolves this problem by using an adaptive coarse graining strategy. In this new method, the domain is divided into many sub domains each with its own coarse graining ratio. When a particle move from one zone to another, the degree of coarse graining changes by either breaking the particles into smaller one or gathering smaller particles into a bigger particle as shown in the attached figure.

We use this adaptive coarse graining technique to simulate hopper flow as shown in the attached figure and the results are compared with classical coarse graining technique of Sakai and Koshizuka. A simulation with originally 7,500,000 particles were taken and resolved into a simulation of 956,689 particles using a fixed coarse graining ratio of 2. Higher coarse graining ratio yielded inaccurate results. With adaptive coarse graining, a total of only 75,000 particles of varying sizes were used. The results obtained from the fixed coarse graining and adaptive coarse graining were comparable, but the fixed coarse graining took 180 hours to simulate the discharge while the adaptive coarse graining took only 7 hours to complete the simulation.