2020 Virtual AIChE Annual Meeting

(109g) Proad (Process Advisor): Health Monitoring Dashboard for Centrifugal Pumps

Authors

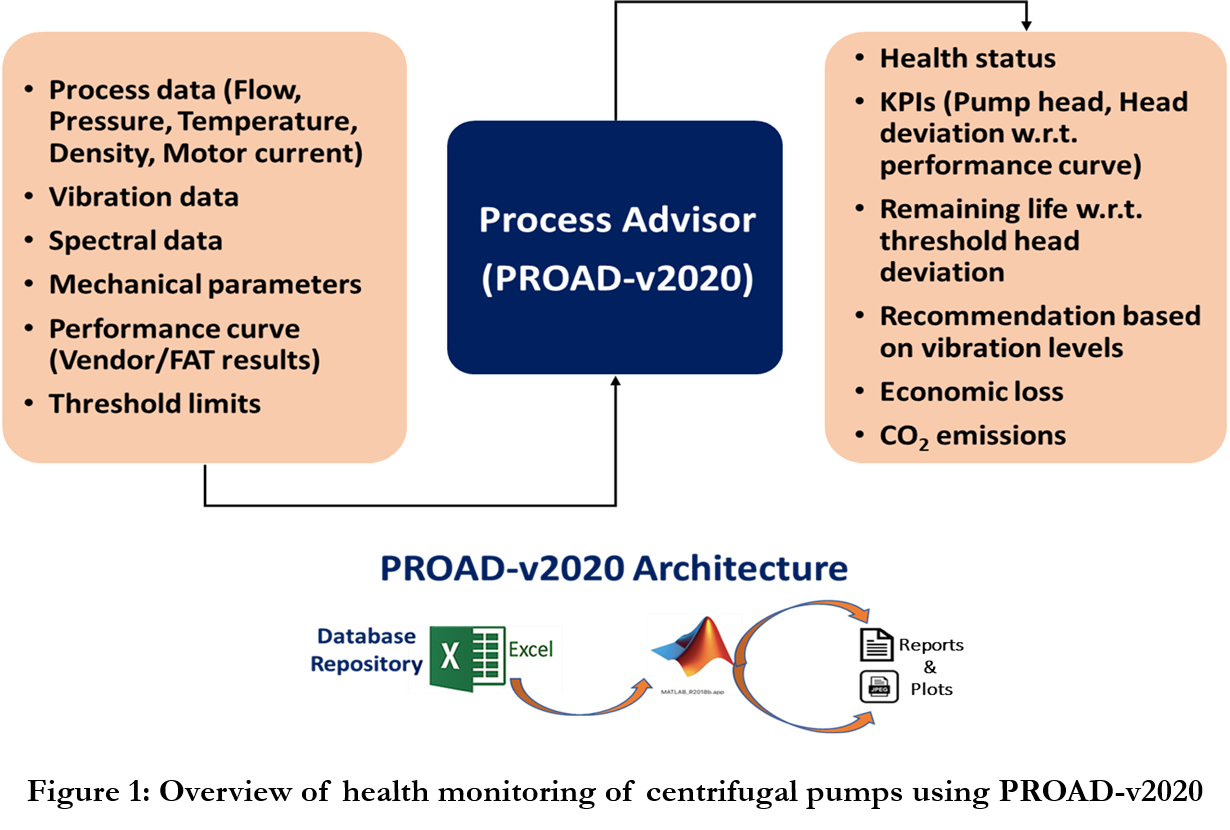

In our work, we have developed a comprehensive methodology that allows health monitoring, diagnosis, and prescriptive maintenance of centrifugal pumps. We adopt a multi-pronged approach where we use process operational data for health monitoring, and equipment-specific data for prescriptive maintenance and fault diagnosis. Process operational data are used to compute and monitor the deviation of the pump head as a function of flow rate (pump head curve) from the vendor-supplied head curve for a fresh pump. Recent trends of these deviations are then used to predict the remaining useful life of the pump w.r.t. a given threshold head deviation. On the other hand, continuous readings from different vibration sensors on a pump are analyzed for trends to prescribe more detailed spectral checks for potential incipient faults. In addition, a diagnostic tool is also developed that analyzes spectral data and recognizes known patterns linked to various mechanical faults (such as imbalance, misalignment, bearing damage, cavitation, etc.) common in centrifugal pumps. Our diagnostic tool also has the ability to add new and unknown faults that may arise during the pump operation and get diagnosed by maintenance engineers. Besides these process/mechanical health indicators, we estimate the energy equivalent economic loss and carbon emissions associated with the pump over its operational period.

The above methodologies are implemented within a standalone plug and play desktop application (PROADv2020) easily implementable in any chemical plant without requiring any external software license. The app revolves around a graphical user interface (GUI) â based dashboard built using the MATLAB app designer feature, which displays all pumps on a single screen. Data input to PROAD is via well-directed, interactive, and robust MS-EXCEL templates. Based on different performance and diagnostic metrics, health status of each pump is indicated by specific color codes. Detailed health status and historical performance of each pump are conveyed via reports, and visualized via head, efficiency, vibration, and spectral plots. PROAD maintains a database of all reports and plots for future access. PROAD also has a feature that summarizes the health status of all pumps, thus providing an easy way to assess their performance at once. The GUI of PROAD is developed in consultation with engineers from our industrial collaborator, thus any information obtained from PROAD can be easily interpreted by any industry personnel. An overview of health monitoring of centrifugal pumps via PROAD-v2020 is illustrated in Figure 1.

We have tested PROAD-v2020 on multiple centrifugal pumps with about 20 months of real data obtained from our industrial collaborator. The health status and diagnoses inferred from PROAD were consistent with the performance observed and confirmed by the plant engineers. The tool is currently being tested by our industrial collaborator and refined with their feedback.

Acknowledgement

This project is funded under Energy Innovation Research Programme (EIRP) Award NRF2017EWT-EP003-020, administrated by the Energy Market Authority (EMA). The EIRP is a competitive grant call initiative driven by the Energy Innovation Programme Office and funded by the National Research Foundation (NRF) of Singapore. We would also like to thank our industrial collaborator for providing plant data and feedback on PROADâs development.