"We're on schedule for our target delivery date."

"What's that?! You want it a MONTH earlier?"

I'm sure that many of you have had conversations just like that one in your career. It is human nature to want to add value by reducing time to completion. The faster you are to market, the quicker you can begin to profit. At Zeton Inc., they are fine-tuning the art of just-in-time engineering, and Adam Whalley talked about how they shave weeks or months off already tight schedules for completion of their pilot plant construction projects.

Traditional approaches

All projects have schedule pressures, even at times when they are ahead. Some of the traditional responses to a request (or command) for an earlier ship date include:

- Expediting suppliers

- Applying more resources, working overtime, etc.

- Relaxing some of the specifications

- Substituting more available construction materials

These traditional methods can be effective, but often have points of diminishing returns. Two more fitters on the skid may work, but four won't fit! Changes may also add back time in the re-engineering process, both to accomplish the change and to deal with any unexpected resulting consequences.

Just-in-time engineering

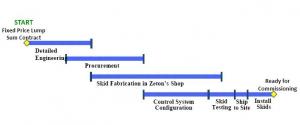

In a traditional pilot plant project, total design engineering (TDE) is completed prior to construction and the procurement process. In this case, full bid package and design specs are required to complete a quote. An alternative approach, however, experience and background data from past projects can allow an approach that permits an overlap of engineering and construction. Zeton practices just such an integrated design-build philosophy.

Thanks t0 the company's access to data and metrics from their hundreds of past projects, and the co-location of the engineering and manufacturing facilities, they can begin commercial, construction, and procurement processes before TDE is finished. In fact, some of these processes start when only half of the TDE is complete.

Typically, when TDE is at 50%, a lump sum quotation can be finalized for the customer. In addition,

procurement for many of the components can begin. With about 75% of the TDE complete, fabrication starts. This overlap of engineering and traditionally post-engineering efforts allows many weeks to be eliminated from the schedule.

Changes on the fly

By having the engineering and production facilities co-located, issues and changes can be rapidly assessed, evaluated, and solutions implemented. Thus, the final stage of TDE completion is occurring in real time as final design and construction issues are resolved. There is no back-and-forth lag time between fabricator and engineer, no costly and time consuming redesign and re-submittals, and a learning and cooperative working relationship develops that speeds this and future projects.

In addition, as much unit testing as possible is done on the manufacturing floor to save startup time, and identify problems early. Often, replacement parts are ordered and drop-shipped to the final destination as the unit itself is shipping, saving days of transportation time.

Finally

Zeton has found that it can save 4-14 weeks with this just-in-time engineering approach. Though your situation will differ, many of these lessons could help you achieve such step-change schedule reductions.