Page 8 - Equipment Identification - CCPS Safe Work Practice

P. 8

Strategies and Effective Practices

to Manage and Mitigate Hazards

Valve Tags

V

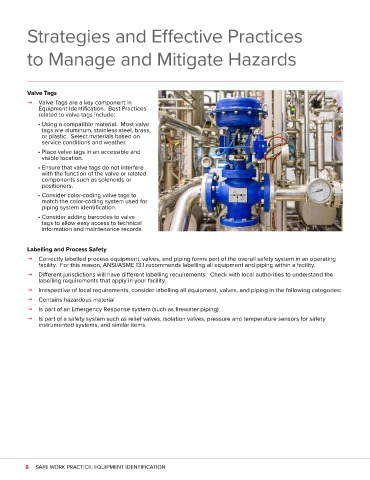

g alve Tags are a key component in

Equipment Identification. Best Practices

related to valve tags include:

• Using a compatible material. Most valve

tags are aluminum, stainless steel, brass,

or plastic. Select materials based on

service conditions and weather.

• Place valve tags in an accessible and

visible location.

• Ensure that valve tags do not interfere

with the function of the valve or related

components such as solenoids or

positioners.

• Consider color-coding valve tags to

match the color-coding system used for

piping system identification.

• Consider adding barcodes to valve

tags to allow easy access to technical

information and maintenance records.

Labelling and Process Safety

C

g orrectly labelled process equipment, valves, and piping forms part of the overall safety system in an operating

facility. For this reason, ANSI/ASME 13.1 recommends labelling all equipment and piping within a facility.

D

g fferent jurisdictions will have different labelling requirements. Check with local authorities to understand the

i

labelling requirements that apply in your facility.

g espective of local requirements, consider labelling all equipment, valves, and piping in the following categories:

rr

I

g ontains hazardous material

C

I

g s part of an Emergency Response system (such as firewater piping)

I

g s part of a safety system such as relief valves, isolation valves, pressure and temperature sensors for safety

instrumented systems, and similar items.

8 SAFE WORK PRACTICE, EQUIPMENT IDENTIFICATION