Page 7 - Energy Isolation - CCPS Safe Work Practice

P. 7

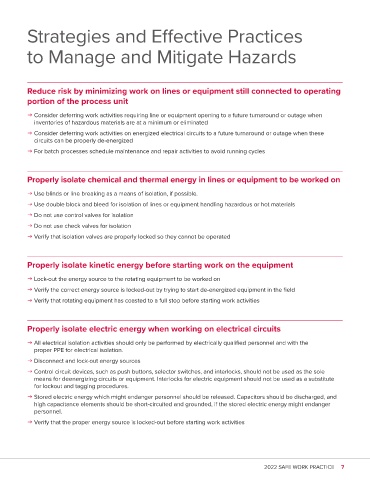

Strategies and Effective Practices

to Manage and Mitigate Hazards

Reduce risk by minimizing work on lines or equipment still connected to operating

portion of the process unit

g Consider deferring work activities requiring line or equipment opening to a future turnaround or outage when

inventories of hazardous materials are at a minimum or eliminated

g Consider deferring work activities on energized electrical circuits to a future turnaround or outage when these

circuits can be properly de-energized

g For batch processes schedule maintenance and repair activities to avoid running cycles

Properly isolate chemical and thermal energy in lines or equipment to be worked on

g Use blinds or line breaking as a means of isolation, if possible.

g Use double block and bleed for isolation of lines or equipment handling hazardous or hot materials

g Do not use control valves for isolation

g Do not use check valves for isolation

g Verify that isolation valves are properly locked so they cannot be operated

Properly isolate kinetic energy before starting work on the equipment

g Lock-out the energy source to the rotating equipment to be worked on

g Verify the correct energy source is locked-out by trying to start de-energized equipment in the field

g Verify that rotating equipment has coasted to a full stop before starting work activities

Properly isolate electric energy when working on electrical circuits

g All electrical isolation activities should only be performed by electrically qualified personnel and with the

proper PPE for electrical isolation.

g Disconnect and lock-out energy sources

g Control circuit devices, such as push buttons, selector switches, and interlocks, should not be used as the sole

means for deenergizing circuits or equipment. Interlocks for electric equipment should not be used as a substitute

for lockout and tagging procedures.

g Stored electric energy which might endanger personnel should be released. Capacitors should be discharged, and

high capacitance elements should be short-circuited and grounded, if the stored electric energy might endanger

personnel.

g Verify that the proper energy source is locked-out before starting work activities

2022 SAFE WORK PRACTICE 7