(117an) ISO 9001-2015 and Risk Mindedness in the Management of Heat Exchangers in Ammonia Synthesis Process Adrian Lutchman, Sandra Bissoon-Maharaj, Devon Indar, Festus Addo-Yobo**

AIChE Spring Meeting and Global Congress on Process Safety

2021

2021 AIChE Virtual Spring Meeting and 17th Global Congress on Process Safety

Global Congress on Process Safety

GCPS Poster Session

Wednesday, April 21, 2021 - 3:00pm to 4:00pm

interconnected processes for which heat exchangers perform a critical function because

reaction is exothermic and heat removal is important. There is low conversion

per passage through the reactors due to equilibrium effects, refrigeration is

used to remove ammonia from gases before recycling unreacted feed gases back

into the reactors. The design has been optimized, however, there are issues

with plant reliability which require attention.

Thinning

of heat exchanger tubes due to erosion and corrosion cause them to break down

unpredictably leading to unplanned shut-down of plants thus reducing

productivity and reliability. The desired outcomes of plant performance

encompass: safety, operational efficiency, effectiveness, utilization of

resources and productivity. Therefore, tube thinning poses a risk to plant

operation. The revision of the ISO 9001 Standard to the 2015 version makes it a

requirement to address risk in all aspects of the Quality Management System

(QMS) and places the responsibility on top management. To meet these

requirements, Process Control Engineers must necessarily have conversations

with custodians of the QMS, in order to optimize the plant performance, whilst

minimizing risks and mitigating their impacts continually.

Our

research work on the ammonia process is focused on minimizing the impact and

frequency of tube failure. Heat exchanger thinning is a progressive process.

The risk factors underlying tube thinning are diverse and include: control of the

pH of Boiler Feed Water (BFW), the chemical composition of the steel, the

velocity of the cooling water and steam inside the tubes, the temperature in

the tubes, and the geometry of heat exchangers. In many cases, non-destructive

testing can identify tubes that have thinned significantly, which be blocked

off to avoid water leaking from them to the process stream. In this first paper

we use HYSYS to model the performance of the heat exchanger network used in a

KBR Ammonia Plant before and after heat exchanger tubes were blocked off. We

investigate numerically, the influence of three interacting process variables which

influence the risk of tube failure: BFW flowrate, process gas temperature, velocity

of steam-water mixture in the tubes, and use heuristics to create a map of the

risk posed to delivering desired process outcome.

The Method

The HYSYS

models cannot account for the presence of finned tubes, however we compensate

for their presence by taking account of increased surface area of finned tubes

without changing their resistance to heat transfer significantly.

BFW flowrate

influences the steam quality in the tubes, its velocity and the temperature.

The temperature in the tubes is influenced by the temperature of the process gas

on the shell side of the exchangers.

The

analysis of the 3D flow of vapour-liquid cooling fluid in the tubes is modelled

by the control volume finite element method. Case studies in which the gas

flowrate and temperature are varied enabled us to determine the minimum BFW

flowrate required conform to manufacturer guidelines with respect to steam weight

(less than 30%).

Results

The major

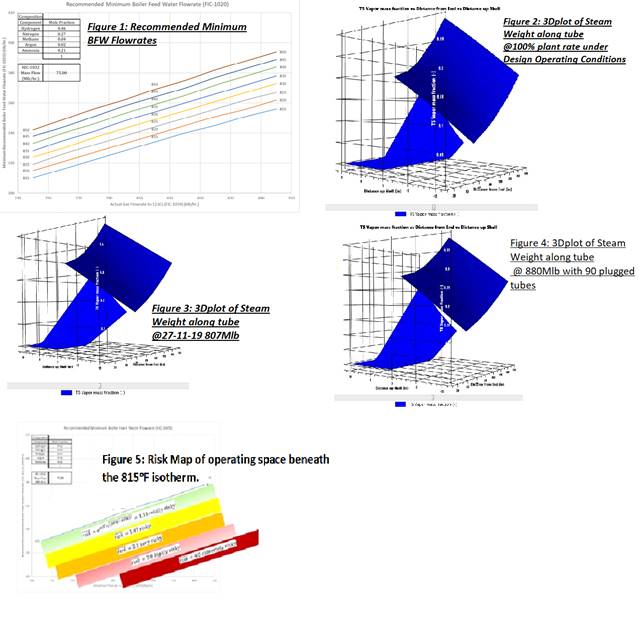

findings of this work are summarized in figure 1 to 5 below:

Figure 1

shows the predicted minimum flowrate of the BFW required as a function of process

gas flow presented as isotherms with process gas temperature as the parameter.

The quality of the steam is known to affect erosion rates and therefore their

prediction is also presented.

Plugging

of the tubes resulted in the following;

Tube Failure on Exchanger 123C2A

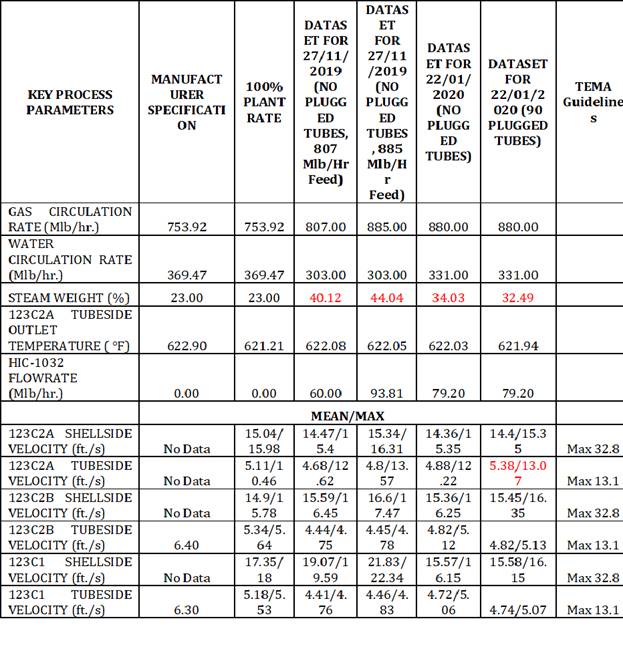

The

thermal and hydraulic characteristics inferred from the rigorous models with

special attention paid to the temperatures, vapour fractions and velocities in

123Cs before and after failure are shown in the table below. An increase in the

mean temperature difference (MTD) was observed and also an increase in the mean

tube side velocity and the maximum tube side velocity.

For all

datasets, most process parameters are within the acceptable regions for safe

operation, with the exceptions of the steam weight and the tubeside fluid

velocity experienced in a period prior to failure and after.

The steam

weight under these conditions was calculated to be 40.1% which is significantly

above the manufacturer’s operating limit of 30%. Thus, the potential for

thermal stress on the exchanger is predicted.

The

maximum tubeside velocity for the 123C2A was calculated to be 12.62 ft./s which

is above the recommended 8ft./s and very close to the maximum 13.1 ft./s. This

limit is specified by Tubular Heat Exchanger Manufacturer’s Association (TEMA)

for tubes that do not contain turbulators or any inserts.

It can be

seen from Figure 2 (design operating regime) that the steam weight in the

123C2A tubes are all below the recommended limit of 30%. Steam weight is

closely related to the velocity experienced on the tubeside, under these

conditions the tubeside velocity is 10.46 ft./s which although high, is still

below the TEMA limit.

In Figure

3 the 3-D analysis of the steam weight in the 123C2A tubes dataset show that

some tubes have a steam weight of greater than 40% with a maximum of 48%. The

resultant tubeside velocity reaches a maximum of 12.62 ft./s. This is a high-risk

operating regime.

After

plugging damaged tubes, it was found from the 3-D analysis of the steam weight

in the 123C2A tubes that the tubes have steam weight of greater than 35% and a

maximum of 38% (Figure 4). The resultant tubeside velocity reaches a maximum of

13.07 ft./s. Though the steam weight is lower than the previous dataset, the

tubeside velocity is higher due to the fact that the boiler feed water flowrate

is greater (331 klb/hr. vs 303klb/hr.). The higher boiler feed water flowrate

coupled with the higher-than-recommended steam weight is a matter of concern.

Based on

the 3-D analysis it is observed that the tubes on the exterior of the bundle

closer to the shellside inlet nozzle would be subject to a higher steam weight

and therefore may experience higher velocities. These tubes may be more likely

to fail due to erosion corrosion degradation.

Discussion

The

maldistribution of heat duty is a major concern because the shell can get too

hot leading to dangerous thermal stresses.

The

increase in velocity through the tube side on a heat exchanger in the network,

is of greater concern. The maximum velocity determined within the bundle was

already close to the (TEMA), limit for two-phase flow. This limit is specified

for tubes that do not contain turbulators or any inserts. The increase in

velocity due to plugged tubes pushes the maximum velocity beyond the TEMA

guidelines. This deficiency in the TEMA specification poses additional risks

which requires addressing under the Standard.

Given

that the network’s overall thermal performance was only marginally affected by

the plugging of the tubes, there would be no need to change the operating

conditions to restore performance but rather to tackle maldistribution of the

heat load.

Risk

Assessment

Several

mechanisms that affect tube life can occur simultaneously and involve the

following: high velocities inside the tube will lead to the turbulators coming

into contact with the interior surface and scraping off the corrosion inhibiting

layer to form suspended abrasive micro particles in the fast-moving steam-water

mixtures which further erodes the inhibitor layer as suggested by Levy, Yan,

& Patterson (1986). This leads further surface oxidation of the austenitic

steel at the operating temperatures and their subsequent removal thus

accelerating the thinning process.

Guidelines

for safe operation state that this layer should not be disturbed once formed as

other corrosion mechanisms can begin (Suez Water Technologies and Solutions,

2020).

Figure 5

shows the likelihood of tube failure due to the combination of the risk

sources. It is assumed that the impact of tube failure is constant and

independent of the risk source.

Conclusion

& Recommendations

networks used in Ammonia Synthesis plants for the purpose of detecting risky

plant operating points assessing risk sources when defining a risk management

strategy for safe and productive operation of the plant. margin-left:0in;line-height:normal"> " arial>A requirement in the standard is that risk

management strategies should be iterative and dependent on outcome of actions

taken. That would suggest that in the operation of ammonia heat exchange

networks helpful measurements could include the analysis of cooling water for corro-erosion

products.

TEMA

should provide limits for two-phase flow in tubes with turbulators.

Risk-mindedness

in the Standard requires that finite element analysis of the thermal stresses

of the tube-shell geometry due to the maldistribution of heat load has to be

carried out.

References

Jonas, O.

(2004). FAC and Cavitation: Identification, assessment, monitoring,

prevention. Combined Cycle Journal.

Levy, A.

V., Yan, J., & Patterson, J. (1986). Elevated Temperature Erosion of

Steels. Wear 108, 43-60.

Sinnott,

R. (2005). Coulson & Richardson’s Chemical Engineering Design,

Volume 6, 4th Edition.

Suez

Water Technologies and Solutions. (2020). Handbook of Industrial Water

Treatment Chapter 11- Preboiler & Industrial Boiler Corrosion Control. Retrieved

from

https://www.suezwatertechnologies.com/handbook/chapter-11-preboiler-and-...

Checkout

This paper has an Extended Abstract file available; you must purchase the conference proceedings to access it.

Do you already own this?

Log In for instructions on accessing this content.

Pricing

Individuals

| AIChE Pro Members | $150.00 |

| AIChE Emeritus Members | $105.00 |

| Employees of CCPS Member Companies | $150.00 |

| AIChE Graduate Student Members | Free |

| AIChE Undergraduate Student Members | Free |

| AIChE Explorer Members | $225.00 |

| Non-Members | $225.00 |