(301h) Proad (Process Advisor): Health Monitoring Dashboards for Compressors and Insulations

AIChE Annual Meeting

2022

2022 Annual Meeting

Computing and Systems Technology Division

Industrial Applications in Design and Operations

Tuesday, November 15, 2022 - 2:36pm to 2:54pm

The maintenance of critical assets (or equipment) in a chemical plant is of utmost importance in ensuring the reliability, security, and reputation of the investing companies. With the advent of Industry 4.0 due to the rapid rise in digitalization and improved computing technologies, prescriptive maintenance is now seen as the most promising maintenance strategy in ensuring the safety, longevity, and optimal performance of a chemical equipment. In our work, we have integrated the concepts of machine learning and data analytics with the information and insights from our industrial collaborator in developing robust and easy-to-use tools that will aid the plant engineers in monitoring and maintaining their respective systems using the available plant data. Based on our previous AIChE 2020 and AIChE 2021 presentations on centrifugal pumps [1] and filters [2], we will be introducing our PROAD dashboards for the health monitoring of compressors and the insulation of pipelines, which are common and critical equipment routinely used in the chemical and oil & gas industries.

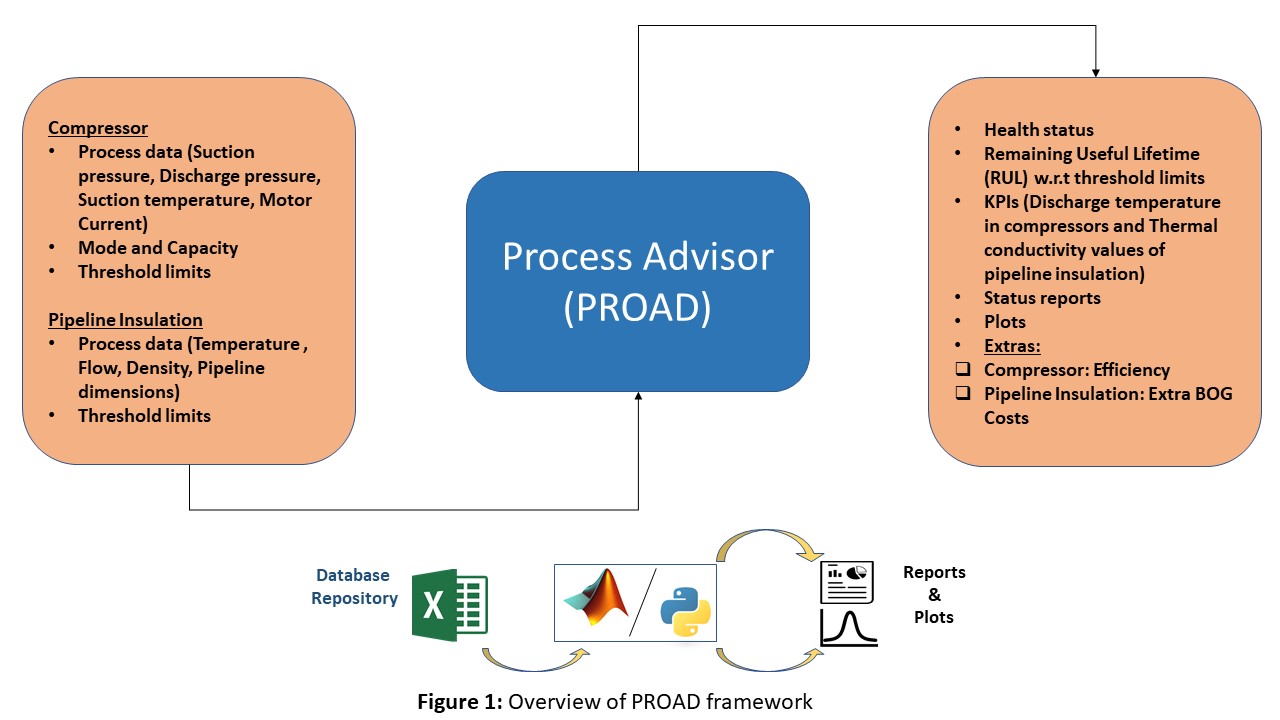

In these works, we have developed comprehensive methodologies through a mixture of data-based and first principles model-based machine learning approaches that execute health monitoring, fault diagnosis, and fault prognosis actions on these systems. The available process operational data are used to compute the deviations in the discharge temperature through a semi-empirical model (in compressors), and the thermal conductivity values of insulation using graph theory (in pipelines). These estimated deviations are utilised as the system’s health indicators (HI) in detecting the presence or absence of faults in the system. On the first occurrence or detection of a fault, the system’s remaining useful lifetime (RUL) w.r.t to a given upper limit threshold, is estimated using the latest trend of the calculated HI values. Besides these monitoring actions, our dashboards can estimate the compressor’s efficiency and the yearly costs incurred due to extra BOG generation because of the deterioration in pipeline insulation.

The above methodologies are implemented in a plug-and-play form of dashboard, that is distributed in the form of an executable file for installation on any PC or laptop of a chemical plant. The developed tools are open source in nature and do not require the installation of any third-party software licenses. These tools utilize graphical user interface (GUI) based dashboards built using the MATLAB app designer feature (compressor) and QT designer & Python (insulation) respectively. These dashboards display all the compressors and pipeline headers on a single screen. The requisite system data is fed in the form of MS-Excel templates in a robust and interactive manner. Based on the conducted analysis and the different performance metrics, the health status of each equipment is indicated using specific colour codes. Detailed plots, health status reports, and historical data of each compressor or pipeline insulation can be accessed and are maintained by the PROAD tools as part of their database for future usage. The GUI of these tools was developed in consultation with the engineers and technicians from our industrial collaborator and we believe that these PROAD tools can be used for similar assets in other plants as well, as the tool’s results are easily interpretable by any industrial personnel. An overview of our developed PROAD framework is illustrated in Figure 1.

Our PROAD tools have been validated using 2 years of real data for compressors, and 4 years of real data for pipelines, provided to us by our industrial collaborator. The health statuses and diagnoses obtained using our developed tools were to be found to be consistent with the performances observed and confirmed by the plant engineers. These tools are currently being deployed by our industrial collaborator and further tool modifications are being performed with the help of their timely and constructive feedback.

Acknowledgement:

This project is funded under Energy Innovation Research Programme (EIRP) Award NRF2017EWT-EP003-020, administrated by the Energy Market Authority (EMA). The EIRP is a competitive grant call initiative driven by the Energy Innovation Programme Office and funded by the National Research Foundation (NRF) of Singapore. We would like to thank our industrial collaborator for providing us with the plant data and their feedback towards the development of the PROAD tools. We would like to acknowledge MathWorks for providing their academic license of MATLAB to the National University of Singapore.

References:

- Arnab Dutta, Iftekhar A. Karimi, Shamsuzzaman Farooq. PROAD (Process Advisor): Health Monitoring Dashboard for Centrifugal Pumps. AIChE 2020 Annual Meeting, November 16-20, San Francisco, CA, USA.

- V.Srinivas and Iftekhar.A.Karimi, An Integrated Fault Diagnostic Fault Prognostic Approach for the Health Condition Monitoring of Degrading Systems, AIChE 2021 Annual Meeting, November 7-11,Boston, USA.