(760d) Techno-Economic Analysis of Biofuel Production Via Catalytic Upgrading of Carbohydrates in Paper Sludge

AIChE Annual Meeting

2020

2020 Virtual AIChE Annual Meeting

Environmental Division

Sustainable Fuel from Renewable Resources

Friday, November 20, 2020 - 8:45am to 9:00am

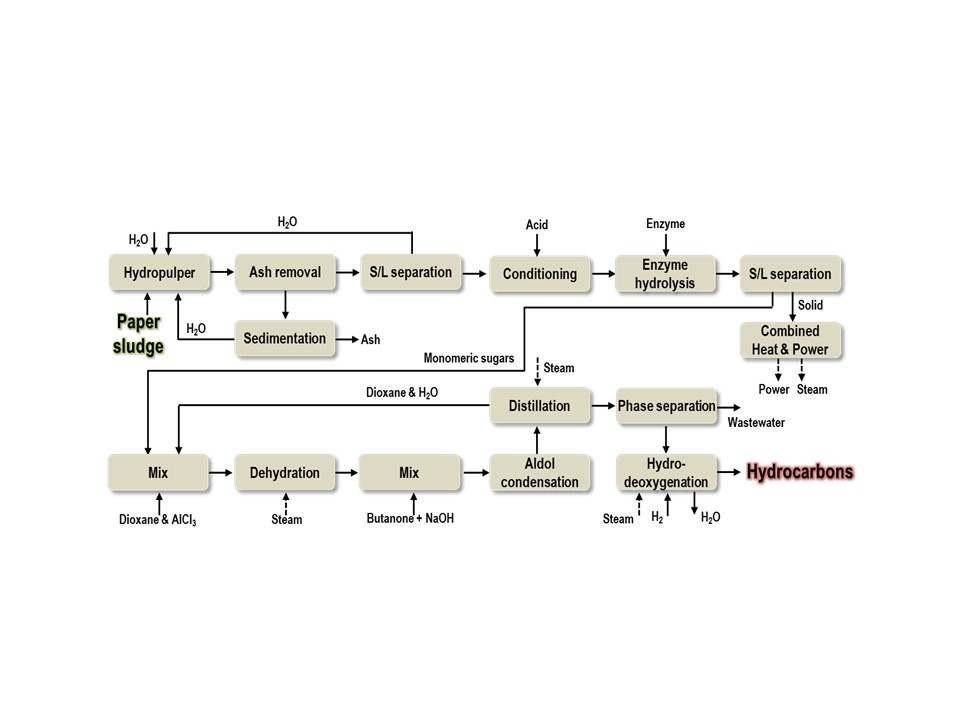

Paper sludge is a solid waste stream from the pulp and paper industry. This material is composed of a fraction of cellulosic fibers removed from the main manufacturing process in the form of fines. In paper sludge, the cellulosic fibers are combined with others such as clays and fillers [1]. Landfilling has become one of the most cost-effective and common practice to handle this waste. This type of disposal not only represents a negative impact for the environment in terms of land use, but it also constitutes an additional cost in waste disposal as high as USD$60 per dry ton. In this study, a chemical pathway for the catalytic conversion of the carbohydrates present in paper sludge into hydrocarbons is proposed. In order to evaluate the economic feasibility, a techno-economic analysis is conducted. In this study, experimental results are used in order to develop a simulation process model, and the same data is used to determine the capital expenditure and the operational expenditure for the techno-economic assessment based on the minimum fuel-selling price of the hydrocarbon product. Aspen Plus is used to solve the rigorous mass and energy balance for each process area. To assess the commercial potential of the bio-based fuel produced, the developed techno-economic assessment was used in order to determine the key parameters affecting the minimum fuel-selling price of the final product. According to the obtained results, the proposed catalytic upgrading pathway processing 750 tonnes of carbohydrates per day yields to a hydrocarbon blend product having a minimum fuel-selling price of $5.97 per gasoline gallon equivalent. In addition, the sensitivity analysis assessment indicates that the solvent (dioxane) to water ratio in the dehydration reaction, the fibers consistency for the hydrolysis reaction, the loss of solvent, and the plant scale are the primary drivers affecting the minimum fuel-selling price of the bio-based fuel obtained.

References

[1] T. W. Jeffries and R. Schartman, “Bioconversion of secondary fiber fines to ethanol using counter-current enzymatic saccharification and co-fermentation,†Appl. Biochem. Biotechnol. - Part A Enzym. Eng. Biotechnol., vol. 77–79, pp. 435–444, 1999.