(639i) Fabrication of a Multifunctional PIM-1 Based Composite Fiber Mat for Applications in Protective Garments

AIChE Annual Meeting

2020

2020 Virtual AIChE Annual Meeting

Materials Engineering and Sciences Division

Multifunctional Composites

Friday, November 20, 2020 - 10:00am to 10:15am

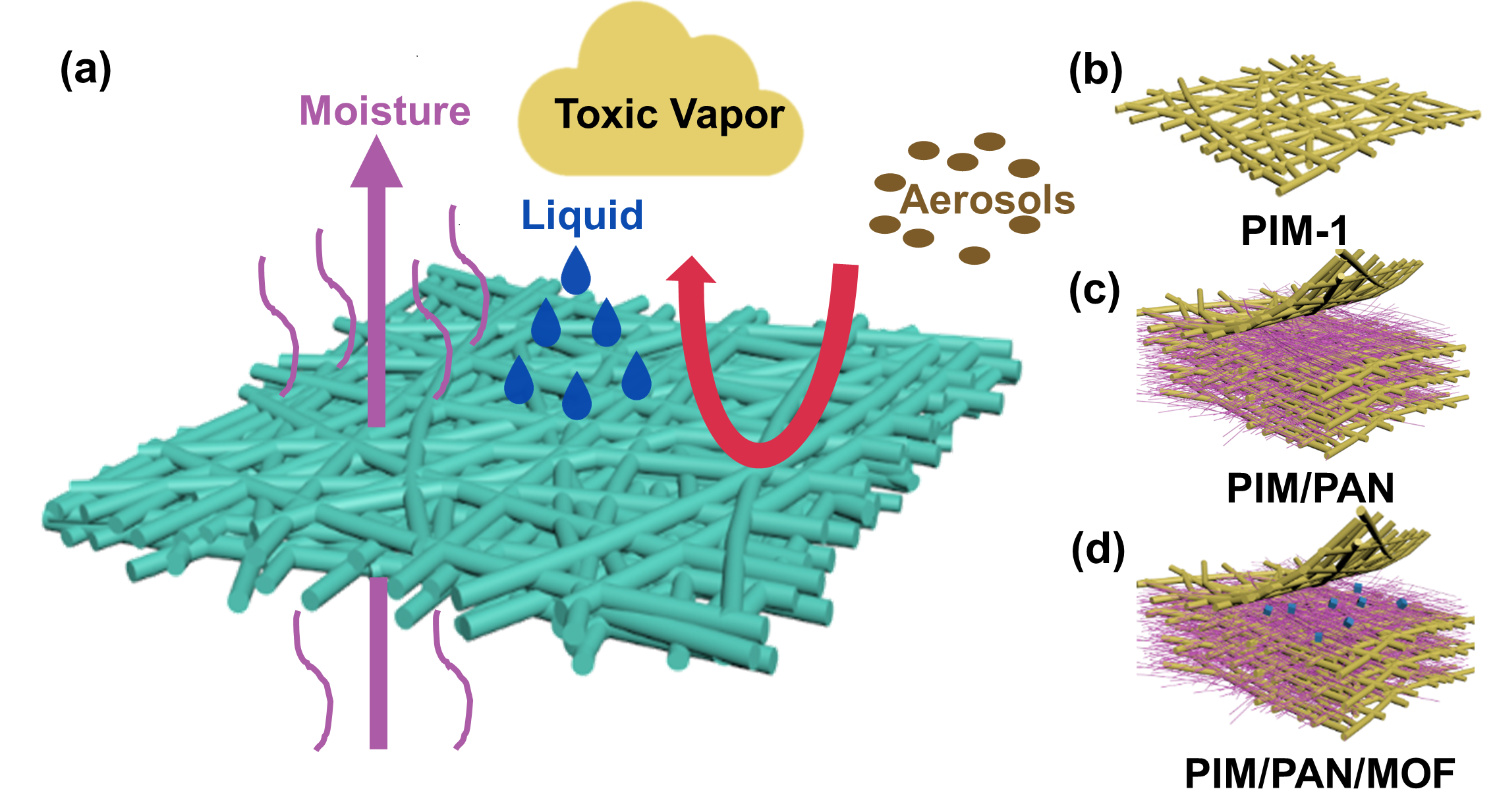

Herein, we present for the first time, a highly sorptive, breathable, mechanically strong aerosol-protective layered fabric with prominent catalytic degradation capability of CWAs, through novel material selection and engineering design. Electrospun PIM-1 fiber web with hierarchical porosity is utilized as a matrix material, preventing toxic gas penetration while providing pathways for air and water vapor molecules. Polyacrylonitrile (PAN) nanofibers assembled with PIM-1 fibers via a layer-by-layer electrospun-deposition approach is shown to achieve significantly enhanced mechanical integrity and filtration efficiency, due to the high polar chemical structure and small fiber diameter of PAN. The subsequent incorporation of UiO-66-NH2 particles, a Zr-based metal-organic framework (MOF), further enhances the sorption capacity while maintaining excellent filtration efficiency, mechanical strength and breathability, and also endows the fiber web with remarkable catalytic degradation towards CWA simulants. The resulting PIM/PAN/MOF composite fiber mat demonstrates unprecedented integrated properties with water vapor transmission rate of 1013 g/m2 ·24hrs, surface area of 574 m2 /g, increased tensile strength (over 70 times compared to neat PIM-1 fiber web), and PM2.5 and PM10 filtration efficiency of 99.88% and 99.94% respectively, comparable to commercial polypropylene (PP) nonwoven textile. This facile and effective fabrication of such multifunctional composite fiber mat is valuable for the design of protective garments in health care, personal protective gear and law enforcement and military uniforms.