(595g) Fabrication of Highly Permeable Polyethersulfone Substrates with Bicontinuous Structure for CO2-Selective Composite Membranes

AIChE Annual Meeting

2020

2020 Virtual AIChE Annual Meeting

Separations Division

Membrane Formation

Thursday, November 19, 2020 - 9:30am to 9:45am

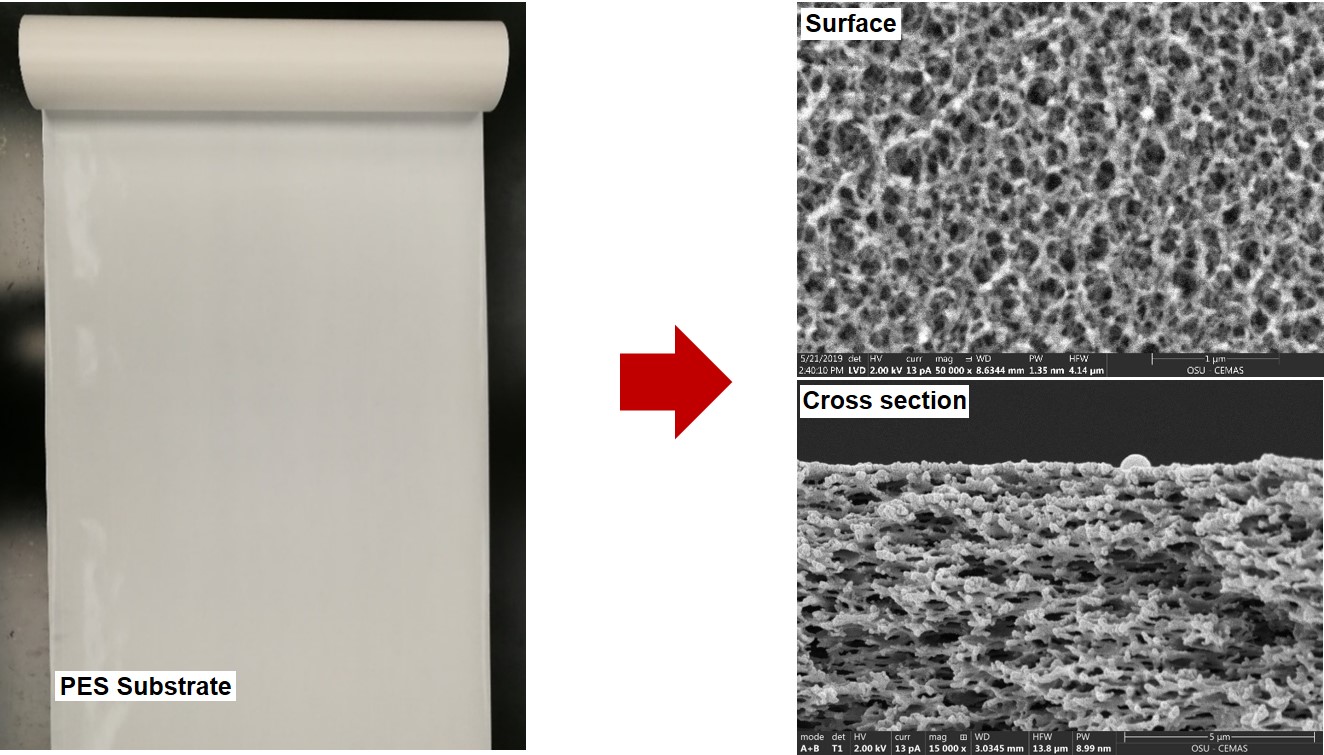

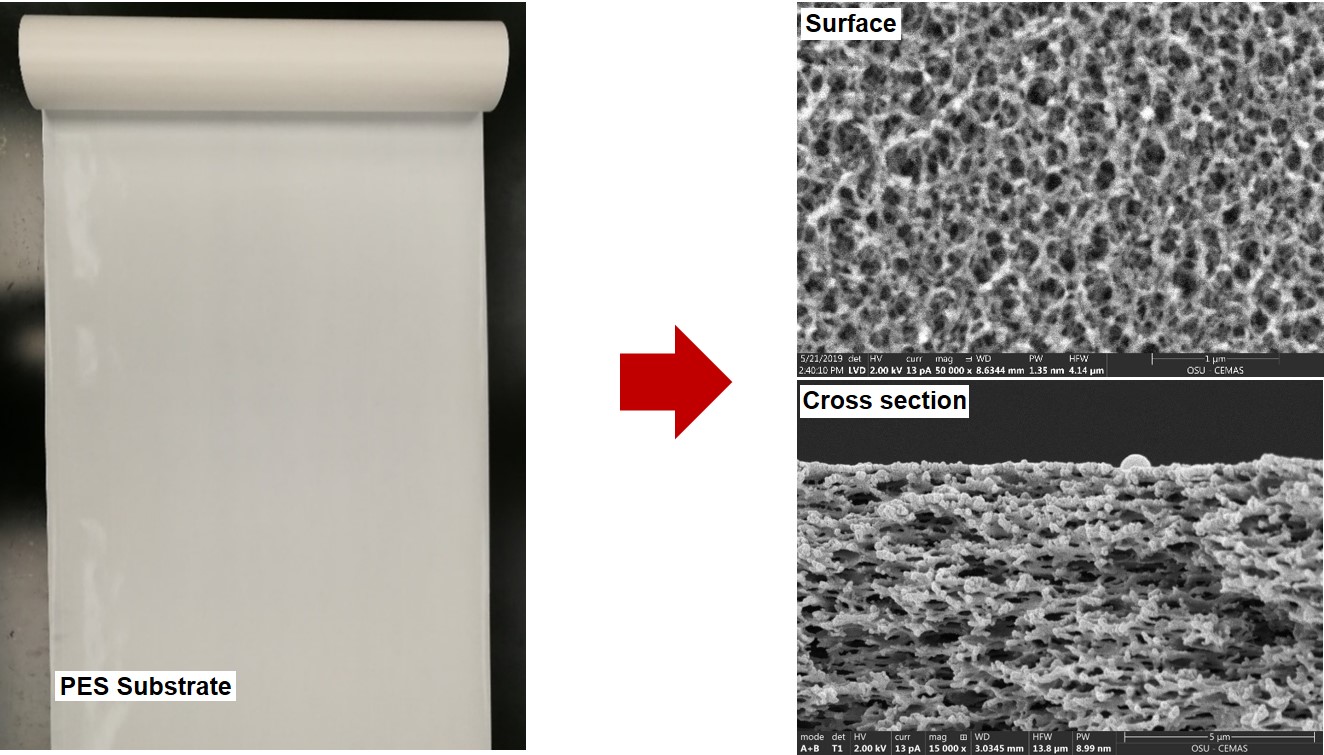

The substrate pore structure has a significant effect on the CO2 transport performance of a thin-film-composite (TFC) membrane. In this study, a novel solvent system comprising 2-pyrrolidone (2PD) and 2-methoxyethanol (2-ME) was used to prepare polyethersulfone (PES) substrates with bicontinuous structure by vapor-induced phase separation, followed by immersion in a nonsolvent, water. Compared with the common solvent, e.g., N-methyl-2-pyrrolidone (NMP), 2PD is a solvent with a lower solubility. However, the solubility was improved by the addition of 2-ME into 2PD. Moreover, the 2PD/2-ME system is more hydrophilic and can decrease the thermodynamic stability of the casting solution significantly. As a result, the phase separation during the membrane formation process was induced via the spinodal decomposition mechanism. The process parameters, including PES concentration, 2PD/2-ME weight ratio, water vapor exposure time, and water bath temperature, were optimized by characterizing the membrane morphologies and the CO2 transport performance. Compared with the baseline PES substrate optimized previously with NMP, the new substrate showed a high surface porosity of 19.9%, indicating a 48.5% increase. Also, the new substrate exhibited a very high CO2 permeance of 133,226 GPU at 57oC, which was 5 times more permeable than the baseline substrate. This high permeance was contributed mainly by the absence of a top dense layer and the presence of highly interconnected pores in the substrate. By using this substrate, the prepared TFC membrane containing amines showed a CO2 permeance of 908 GPU, which was 48 GPU higher than that with the baseline substrate at 57oC. This improvement can be explained well using the resistance-in-series model. The improved CO2 permeance was attributed to both the reduced lateral diffusion and substrate transport resistances. In addition, the scalability of the PES substrate with the bicontinuous structure was demonstrated by the successful roll-to-roll fabrication of a 50-foot long scale-up PES substrate with a width of 21ʺ.