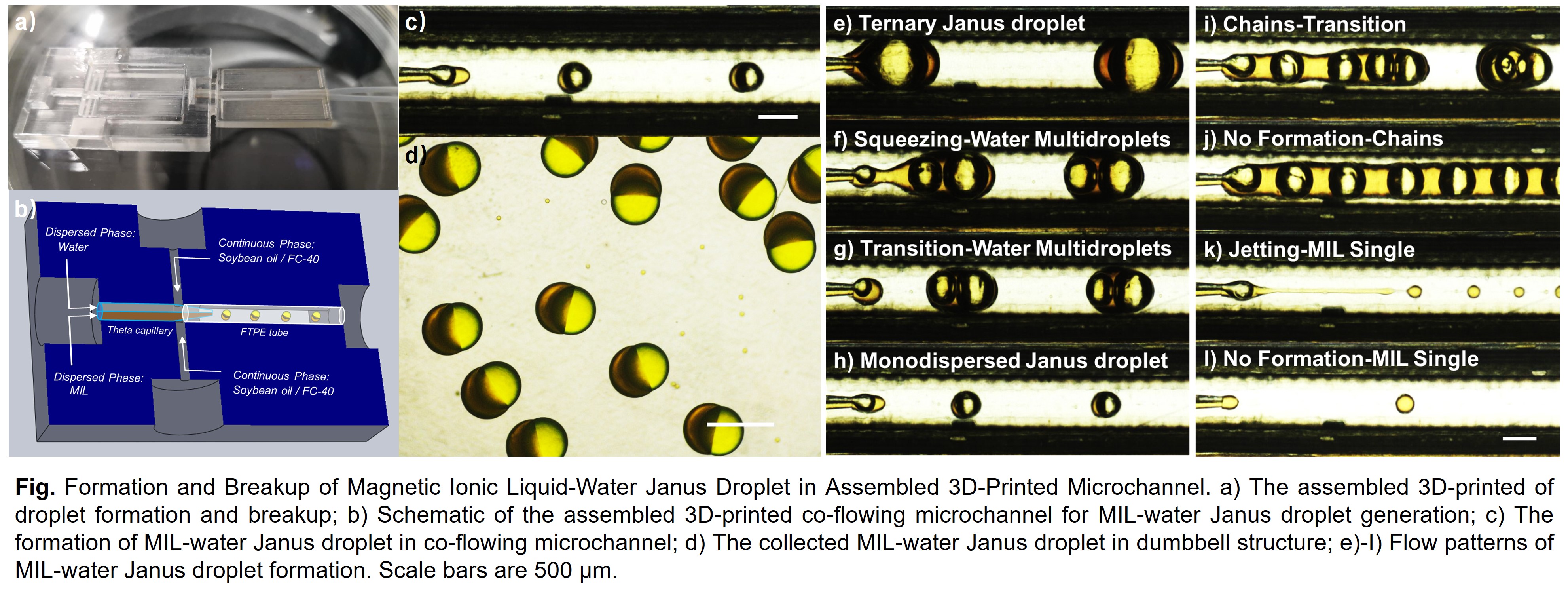

(425a) Formation and Breakup of Magnetic Ionic Liquid-Water Janus Droplet in Assembled 3D-Printed Microchannel

AIChE Annual Meeting

2020

2020 Virtual AIChE Annual Meeting

Engineering Sciences and Fundamentals

Microfluidic and Nanoscale Flows: Multiphase Systems and External Fields

Thursday, November 19, 2020 - 8:00am to 8:15am

Recently, the complex emulsions, owing to multifunction provided by their unique morphologies and multi-compartments, have gained increasing interests for both scientific research and industrial applications. Especially, Janus droplets which composed of two or more compartments with different physically or chemically properties, exhibit potential applications in a wide range of fields including material science, optics, magnetics, bio- and life sciences and so on. Complex microdroplets involved MILs would further achieve manifold functions of MILs and expanded its application fields. However, studies on the formation of IL-based multiphasic droplets in microchannels are still limited due to the complex interfacial properties and high viscosity of the ILs. And the components and structures of multiphasic droplets are largely subject to the restrictions of the materials and geometries of microdevices. 3D printing technology has been emerged as a fast, simple and flexible manufacturing tool for fabrication of microdevices assisted by design software such as computer-aided design (CAD) or Solidworks. Compared to traditional manufacturing method of soft-lithography for microchannels, 3D printing has superior advantages on 3D structures fabrication, on-demand design and rapid prototyping. However, the challenge of removing the uncured resin or support materials from microchannels in stereolithograpy (SLA) and poly-jetting 3D printing limits its resolution and the complexity of microchannels. Therefore, complex geometries are commonly fabricated by assembling different subunits, which can improve the flexibility of multiphasic droplets generation and also reduce the post-processing cost for 3D-printed microdevices.

Herein, we developed an assembled 3D-printed co-flowing microchannel for the [bmim]FeCl4 MIL-water Janus droplets generation. No surfactants added for the sake of the recovery of pure MIL. Special attention is paid to characterize the hydrodynamics of MIL involved Janus droplet formation, where the biphasic dispersed phases have a large difference in physical properties such as viscosity and interfacial tensions. Flow patterns of MIL-water Janus droplets are analyzed and compared with experimental reports of low viscosity systems and IL single phasic droplet formation. Besides, droplet size scaling laws, structure control and morphology evolution of MIL-water Janus droplets are investigated to obtain a deep and systematic understanding of reliable and controllable formation of MIL-involved multiphasic droplet via co-flowing microchannels. Passive droplet breakup has become a hotspot of research, which facilitates droplet size control and production of sample replicates, multiplexing of a large number of droplets. To our best knowledge, Janus droplet splitting in microchannel has not yet been reported. We applied a simple 3D-printed splitting subunit into the study of the breakup of MIL-water Janus droplets in three-dimensional microdevice and achieved the recovery of MIL by the split of MIL-water Janus droplets. This work should be useful for obtaining a deep and comprehensive understanding on the formation, breakup and structure control of IL-based Janus microdroplets in multiphase flow. The generated MIL-water Janus microdroplets are promising candidates for use in applications of catalysis and extraction.

References:

- Bai L, Fu Y, Zhao S, Cheng Y. Droplet formation in a microfluidic T-junction involving highly viscous fluid systems. Chemical Engineering Science. 2016;145:141-148.

- Bai L, Zhao S, Fu Y, Cheng Y. Experimental study of mass transfer in water/ionic liquid microdroplet systems using micro-LIF technique. Chemical Engineering Journal. Aug 15 2016;298:281-290.

- Bai L, Fu YH, Cheng Y. Ionic Liquid-Based Suzuki Coupling Reaction: From Batch to Continuous Microflow System. Journal of Flow Chemistry. Jun 2017;7(2):52-56.

- Bai L, Fu YH, Yao M, Cheng Y. Enhancement of mixing inside ionic liquid droplets through various micro-channels design. Chemical Engineering Journal. Jan 2018;332:537-547.