(230e) Construction Composite Materials As Sustainable End-Use for Coal Extraction Waste

AIChE Annual Meeting

2020

2020 Virtual AIChE Annual Meeting

Materials Engineering and Sciences Division

Composites for Sustainability

Tuesday, November 17, 2020 - 9:00am to 9:15am

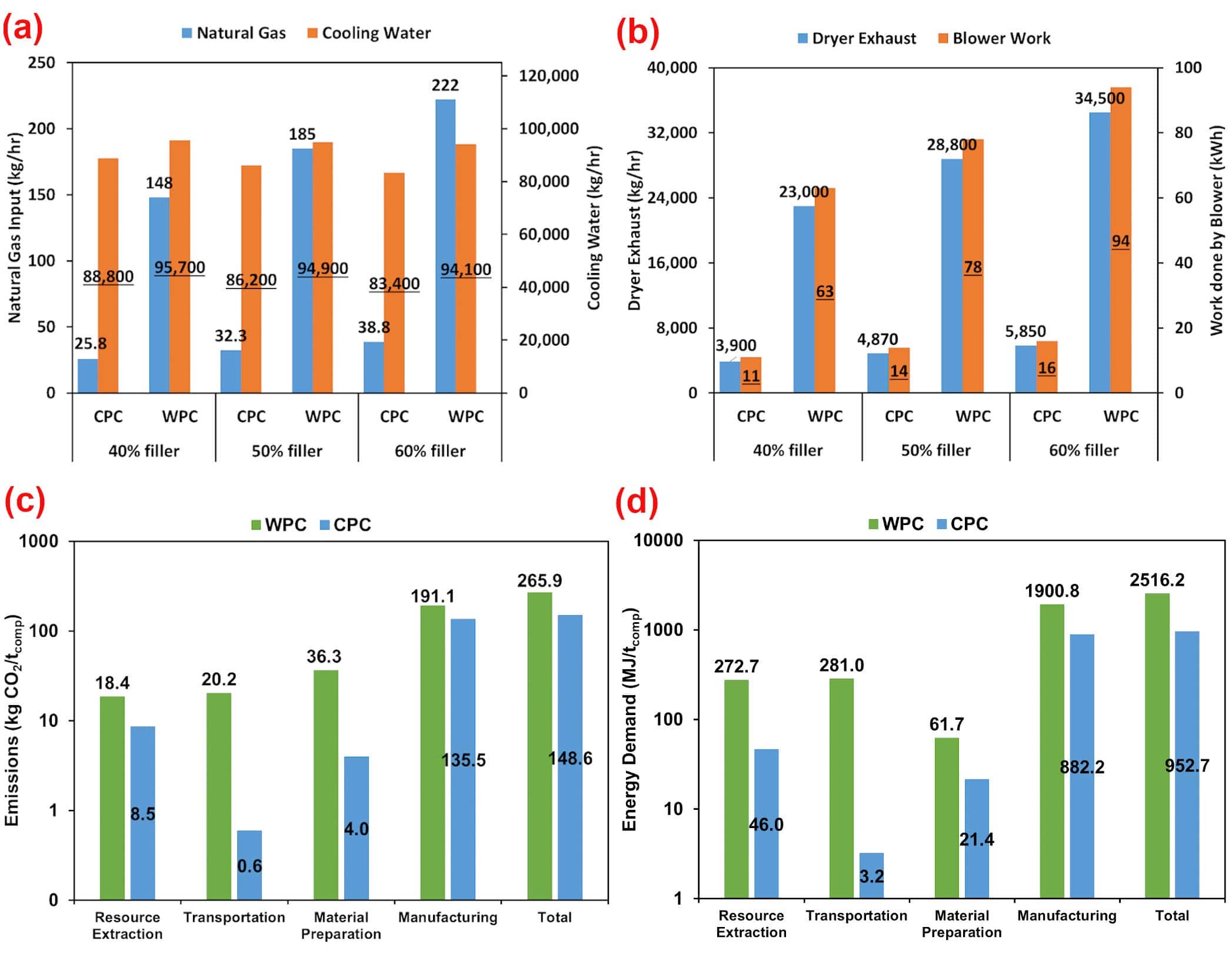

Coal is a potential alternative filler material for composite materials used on construction applications. Utilizing coal residuals located in settling pounds represents an alternative way utilizing this waste material to prevent water pollution and protect the environment. Ohio University (OHIO) and industry partners with the support of the U.S. Department of Energy (DE-FE-0031809) are developing coal plastic composite (CPC) materials for construction applications. CPCs may offer significant advantages over WPCs including lower manufacturing energy intensity and costs, while providing a product with equivalent or superior properties to commercially available WPC products.

CPCs made with subbituminous and bituminous coals have been evaluated and compared to commercially available WPC decking materials. Mechanical testing results indicate CPCs possess higher flexural strength and comparable flexural modulus in comparison to commercial WPC decking products. In addition, CPCs possess oxidation and flammability rating advantages in comparison to WPC, without antioxidant packages.

Aspen Plus simulations and cradle-to-product life cycle analyses (LCAs) developed for WPC and CPC manufacturing indicate CPC products possess advantages in both manufacturing costs and greenhouse gas emissions associated. This presentation will discuss bench-scale CPC R&D and recent commercial-scale CPC manufacturing trials.