Multivariable processes are controlled by a hierarchical structure of control layers. Field devices and regulatory controls manage individual variables, while advanced process control and production control systems coordinate multiple variables to optimize operation.

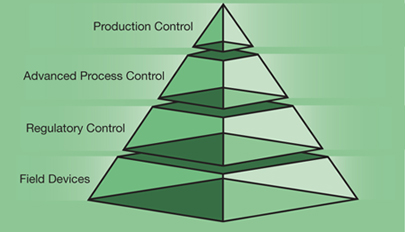

▲ Figure 1. Process control consists of four tiers: field devices, regulatory control, advanced process control (APC), and production control.

Process control can be represented as a hierarchy (Figure 1). The base of the structure is comprised of field devices such as sensors, transmitters, actuators, and valves that measure process variables and implement control actions. Next are regulatory controllers, which keep values measured by field devices, such as pressure, temperature, and flowrate, within specified limits. While regulatory controls tackle each variable individually, the advanced process control (APC) layer evaluates a set of variables, and considers how each one relates to the performance of an entire process unit. However, running a single unit at its local optimum is not necessarily the best strategy for achieving overall profitability of the facility. This is where the production control layer steps in to manage the individual units’ APCs in concert to accomplish plantwide optimization.

From field devices to production control, each layer depends on the previous layer in the hierarchy. The control performance of an individual layer directly affects the stability of the process, the quality of the product, and the costs associated with making the product. This article describes the hierarchical structure in more detail, and explains how model predictive control (MPC) fits into the APC process control layer.

Regulatory control: Managing individual variables

The basic building block of any control system is the regulatory control loop, which consists of three essential pieces:

- an instrument (or calculation) that provides a measure of some process variable (PV) to be controlled, called the control variable (CV). The CV could be a level, temperature, or flowrate, or something more complex, such as a Kappa number (i.e., a measure of the lignin content remaining in wood pulp).

- a controller (or control algorithm in a distributed control system [DCS]) that targets the desired value of the CV, called the setpoint (SP). Relative to the SP, the controller calculates a compensating control move, or output (OP), and sends that signal to the control actuator. The variables affected by the control move are called manipulated variables (MVs).

- a control actuator that implements the control move received from the controller in the process. Control actuators are often valves; other common actuators include louvers and variable-frequency drives on pumps.

Regulatory control loops maintain each control variable at its setpoint to minimize variability if and when conditions change. Regulatory control loops can be broadly classified as either feedback or feedforward.

Feedback control. In feedback control, the controller compares the measured control variable to its setpoint, and computes a compensating move based on the deviation between the actual (CV) and the desired (SP) values. Think about feedback control — only responding to an error after it happens — like driving while looking in the rearview mirror; only after the car is in the ditch can a correction be made to get back on the road again.

Feedforward control. In addition to monitoring the CV, the controller measures a disturbance variable (DV), such as a change in load, and tries to predict the effect this change will have on the CV. This requires prior knowledge of the process response patterns. Unlike feedback control, which compensates for errors after they occur, feedforward control aims to combine feedback with another process signal to minimize errors and compensate as they happen.

PID control

The most common type of regulatory controller is the proportional-integral-derivative (PID) loop (Figure 2). There are an estimated 5 billion control loops running a PID algorithm throughout the world. (Read the Back to Basics series “PID Explained for Process Engineers,” CEP, Jan. 2016, pp. 37–44, Feb. 2016, pp. 27–33, and Mar. 2016, pp. 51–58, for more details.)

Would you like to access the complete CEP Article?

No problem. You just have to complete the following steps.

You have completed 0 of 2 steps.

-

Log in

You must be logged in to view this content. Log in now.

-

AIChE Membership

You must be an AIChE member to view this article. Join now.

Copyright Permissions

Would you like to reuse content from CEP Magazine? It’s easy to request permission to reuse content. Simply click here to connect instantly to licensing services, where you can choose from a list of options regarding how you would like to reuse the desired content and complete the transaction.