With so little of the Earth’s water being potable, desalination is an enormous challenge. Currently, water desalination is incredibly energy-intensive, but a team of researchers led by the Department of Energy’s Oak Ridge National Laboratory has demonstrated an energy-efficient desalination technology that uses a porous membrane made of strong, slim graphene.

The researchers have used graphene in a reverse-osmosis process. A key step to the process is making pores in the graphene that will allow water molecules to flow through but block larger salt ions. Today reverse-osmosis filters are typically polymers. A filter is thin and resides on a support. It takes significant pressure to push water from the saltwater side to the freshwater side. By making the membrane thinner and more porous, the pressure requirements are suddenly lower, and in turn, so are the energy requirements.

Creating the membrane

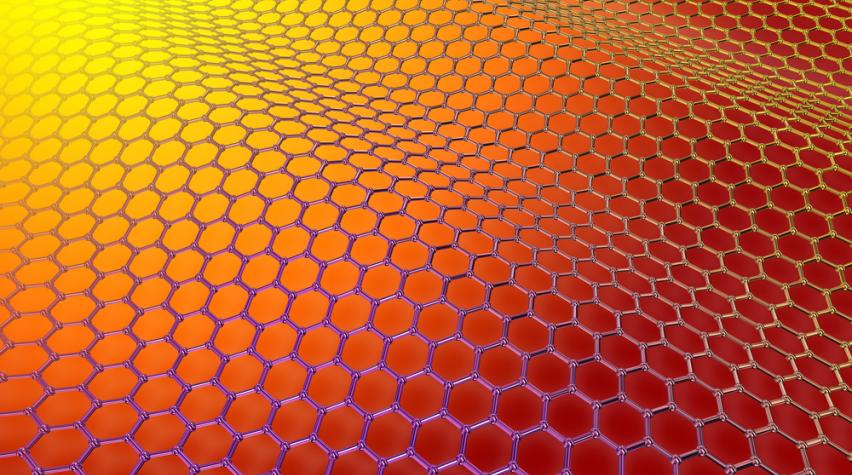

To make graphene for the membrane, the researchers flowed methane through a tube furnace at 1,000 degrees C over a copper foil that catalyzed its decomposition into carbon and hydrogen. The chemical vapor deposited carbon atoms that self-assembled into adjoining hexagons to form a sheet one atom thick.

The researchers transferred the graphene membrane to a silicon nitride support with a micrometer-sized hole. Then the team exposed the graphene to an oxygen plasma that knocked carbon atoms out of the graphene’s nanoscale chicken wire lattice to create pores. The longer the graphene membrane was exposed to the plasma, the bigger the pores that formed, and the more made.

The prepared membrane separated two water solutions—salty water on one side, fresh on the other. The silicon nitride chip held the graphene membrane in place while water flowed through it from one chamber to the other. The membrane allowed rapid transport of water through the membrane and rejected nearly 100 percent of the salt ions.

Boosting efficiency

To figure out the best pore size for desalination, the researchers relied on the Center for Nanophase Materials Sciences (CNMS), a DOE Office of Science User Facility at ORNL. There, aberration-corrected scanning transmission electron microscopy (STEM) imaging allowed for atom-resolution imaging of graphene, which the scientists used to correlate the porosity of the graphene membrane with transport properties. They determined the optimum pore size for effective desalination was 0.5 to 1 nanometers. They also found the optimal density of pores for desalination was one pore for every 100 square nanometers.

The researchers assert that manufacturing the porous graphene membranes used in the experiment is viable on an industrial scale. One challenge that remains: biofouling, or the growths that form on membrane surfaces and clog them.

You can learn more about this research in the press release or in the team’s published work in Nature Nanotechnology.