Co-founders Siva Sivaram and Chris Petti just brought Twin Creeks Technologies out of stealth mode and unveiled the Hyperion 3, a machine they claim will dramatically cut the use of silicon in solar cell production by using high-energy protons to carve silicon wafers into ultra-thin layers. This disruptive change threatens the way things have been typically done in the solar cell industry, but that's exactly what Sivaram and Petti, along with an experienced group of engineers and venture capitalists, want to do.

In the Twin Creeks's Senatobia, Mississippi facility, the two founders stand next to the Hyperion 3, a huge 12-foot appliance, which is 350 sq/ft, and easily the size of large, jacked-up Winnebago that towers over its creators and the spacious factory floor. It outputs 6 MW of modules per year (up from two previous versions), and the company expects to improve it to 10 MW/year.

"We can make less than $0.40/W cells today," Sivaram says, with $0.20/W for silicon and just $0.20/W for processing. Today's rooftop solar PV panels take two years to pay back the power used to create them, he points out; "we can do it in 25 days."

Disappearing into stealth mode

In stealth mode since 2008, Twin Creeks made headlines in 2010 after announcing plans to build a $175 million, 100-megawatt (MW) plant in rural Senatobia, Mississippi, where it would make lower-cost solar panel technology. Then the company went dark again, disappearing back into stealth mode.

Shortly afterwards, a glut hit the global solar panel market - in large part thanks to Chinese solar panel production - driving prices so low that many module manufacturers have flamed out (like former high-flyer Solyndra), often leaving venture capital backers, including the US government, severely burned. Even survivors like Suntech Power and Sunpower continue to struggle with evaporating profit margins. Now, as vertiginous solar panel prices fall below a dollar p/w, and costs hover stubbornly around $0.80 p/w, the trend that, soon, no one will be making money seems to be asserting itself.

While still in stealth mode, Sivaram and Petti gradually moved away from making solar modules and panels, but left intriguing clues - patent information - which revealed a change of direction

into PV manufacturing equipment.

Both men knew they didn't want to compete with other struggling solar cell producers; they'd decided to go for broke and change the rules of the game, selling huge, multimillion dollar proton accelerators industry-wide to cut the cost of producing solar cells in half. That ratcheted up the stakes: After all, that says to a whole industry to adopt Twin Creek's ways or die.

Twin Creek's CEO Siva Sivaram, who feels that he has created a way forward for struggling solar module makers, told GreenTechMedia, "We are a capital equipment company and will remain a capital equipment company. There has been no marketing and there is one sales guy. We are talking now because we have a product ready to ship along with 20 issued patents and a pile on the way."

Hyperion 3: revolutionary technology

Hyperion's new process solves one of solar manufacturing's most severe bottlenecks: today's commercial silicon wafers are freed from blocks of silicon using wire saws in a process that's wasteful, creating unrecoverable kerf loss (sawdust) and wafer fragility.

Twin Creeks allows cell makers to dispense with saws, furnaces, and cell finishing equipment from Applied Materials HCT and Meyer Burger. Sivaram likes to point out, "By eliminating excess material, we will help solar manufacturers produce modules that compete with grid power and open up new markets for chip makers."

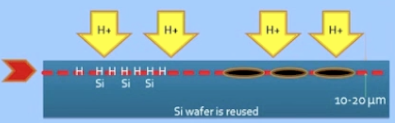

Basically, Twin Creeks' Hyperion, using a process called Proton-Induced Exfoliation (PIE), operates like a particle accelerator, using high current and high voltage, it slams hydrogen atoms into a standard 200-micron piece of silicon where they embed at a fixed depth and form microbubbles. When heated in furnace during a second step, that layer cleaves off or "exfoliates," becoming a very thin 20-micron silicon slice. The remaining silicon block is then used again and again. (watch a detailed demo)

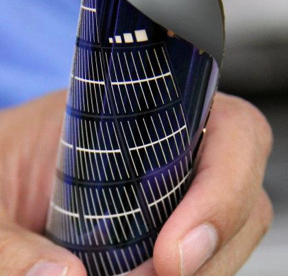

There is no kerf loss, reducing 90 percent of the silicon processed. And thinning down to 20

microns has another benefit: the normally rigid monocrystalline wafer becomes flexible, so all it needs is a laminate to make modules.micron

Hyperion can eliminate several dozen pieces of equipment on a typical 100-MW solar manufacturing line, as well as slurry and thick wafers. But this isn't a cheap fix - Twin Creeks will only ball-park the price at several million per unit. And a 100 MW solar photovoltaic line would need ten of these 10-MW tools, and a gigawatt-sized factory would have 100.

Also, Twin Creeks isn't the only company working on the "wafer" bottleneck. Earthtechling reports that 1366 Technologies says its process reduces four separate manufacturing steps into a single, low-cost continuous process and greatly reduces silicon waste by forming individual wafers directly from a bath of molten silicon. The company has also won a $150 million loan guarantee from the U.S. Department of Energy.

But while 1366 is still working to move to commercialization, Twin Creeks said Hyperion 3, the

company's first commercial offering, is available for shipment now.

"I sell capital equipment," Sivaram confidently says, moving from stealth mode into hype mode. "I want to be able to sell it to every cell and panel maker in the world, so I'm not the one laying out the last penny on the margin and fighting for panel and cell price."

And $93 million in private equity and another $50 million from the State of Mississippi back up his causal bravado. Certainly, if you think about it, at this point in the solar PV bankruptcy cycle, the billions sunk into module companies isn't working out so well.