Researchers at MIT have developed a new photovoltaic system that can generate electricity with no sunlight at all--just heat. While thermo-photovoltaics is at least 50 years old, a new way of nanofabricating the surface of the material to convert heat into precisely tuned wavelengths of light--matching the precise wavelengths that PVs convert to electricity--makes them much more efficient.

The MIT press release by Nancy W. Stauffer adds:

Based on that technology, the MIT researchers have fabricated a button-

sized power generator that's fueled by butane, can run three times longer than a lithium-ion battery of the same weight, and can be recharged instantly by snapping in a tiny cartridge of fresh fuel. Another device, powered by a radioisotope, should generate electricity for 30 years without refueling or servicing--an ideal source of electricity for spacecraft that head out of our solar system.

Creating perfect spectral matching

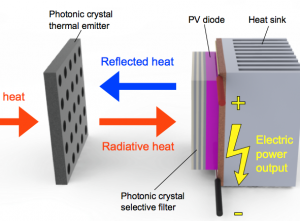

In a typical TPV system, a burning hydrocarbon heats up a thermal emitter, which radiates heat and light onto the PV diode, generating electricity. Because the thermal emitter is not as hot as the sun, its radiation includes far more infrared wavelengths. Although newer "low band-gap" PV materials can absorb more infrared radiation than standard silicon PVs can, much of the heat is still wasted, so efficiencies remain relatively low.

The solution, says MIT researcher Ivan Celanovic, is to design a thermal emitter that radiates only the wavelengths that the PV diode can absorb and convert into electricity. "If you have perfect spectral matching between your heat source and your PV diode, you'll get optimal efficiency for the overall system," he says.

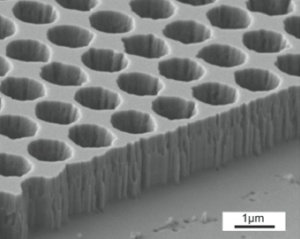

"But how do we find a material that has this magical property of emitting only at the wavelengths that we want?" asks Marin Solja?i?, associate professor of physics. The answer: make a photonic crystal. Take a sample of material, and on its surface create some nanoscale features--a repeating pattern of holes or ridges. Light will now propagate through the sample in a dramatically different way than it did when the material was in its natural form.

Designing the photonic crystal

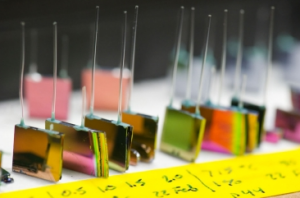

The researchers chose tungsten for the photonic crystal. To transform tungsten into a photonic crystal, they created an array of tiny, cylindrical cavities on the surface--billions of regularly spaced, uniform nanoscale holes. When the slab heats up, it generates a bright light but now with an altered emission spectrum, as described in the journal Physical Review A.

Why? Each pit acts as a resonator, capable of giving off radiative heat at only certain wavelengths. Celanovic offers as an analogy an acoustic resonator. "It's kind of like when you put a seashell next to your ear and you hear a humming noise. You hear the noise amplified at the resonant frequencies of the seashell cavity. It's the same principle, the same physics, but rather than acoustic resonance, this is electromagnetic resonance," he says.

Adding another photonic crystal on the face of the PV diode

The diagram to the right shows the setup of the photonic crystal-enabled TPV system.

Despite careful tailoring, the tungsten emitter delivers some heat at wavelengths that the PV diode cannot convert into electricity. To prevent that waste, the researchers mount another photonic crystal on the face of the diode, this time fabricated with a series of alternating layers of silicon and silicon dioxide--a nanostructure that can be tailored to transmit certain wavelengths and reflect others. Here, it reflects any radiation at unacceptable wavelengths back to the tungsten emitter, where it is reabsorbed and subsequently reemitted to provide more heat at wavelengths that the PV diode can use.

Finally, the researchers are looking at ways to use their photonic crystal to improve the conversion of solar energy into electricity. For example, optical concentrators such as parabolic mirrors could focus solar radiation onto a photonic crystal absorber and emitter, which would reshape the solar spectrum to better match the properties of a PV cell.