Bits and parcels of the latest buzz on sustainability were flashing through my mind during my quite evening walk along the Fort Patrick Henry lake in Warriors Path State Park here in Kingsport, in the midst of crickets and birds chirping.

I began to wonder if the word "SUSTAINABILITY" was still just a buzz word or has the world of chemical engineers identified a working definition for it yet? Does the scope really matter or can we leave it to the perception of the beholder?

We all know that sustainability ranges across industries, across disciplines and across behavior. Folks cutting down on their fatty food intake, opting to walk, bike, and car pool instead of igniting the gas-guzzlers, consuming locally grown organic foods are some of the efforts made by 'common man' toward sustainability or are at least perceived to be so by fellow citizens.

What Does Sustainability Mean for Chemical Engineering?

The Chemical engineering community is addressing the subject by gearing much of the recent academic research toward sustainability, making it the theme of conferences--including the recently held ISCRE-21, centered on Green Chemistry and Sustainability. Many professional organizations are establishing Sustainability forums and consortiums.

The Chemical engineering discipline extends beyond the physical and chemical sciences to include the biological sciences--reflected by bio and green modifiers in the names of chemical engineering departments. Curricula is being modified to include life sciences and various standard texts such as Chemical Reaction Engineering and Fundamentals of Momentum, Heat, and Mass Transfer, which discuss bioengineering concepts and illustrations.

The workable items wrapped under the sustainability umbrella, as seen by chemical engineers, are:

- alternate energy sources (like solar, wind)

- alternate feedstock (biobased) for energy (bioenergy) and chemicals (biorefinery and biomass to liquids)

- alternate raw materials

- Green Processes with minimal footprint and minimal environmental impact

- Process intensification that minimizes energy/exergy losses

- Recycling

- Providing quality water, food and medicines

In general, the processes, across many industries, are/will be analyzed using LCA (life cycle analysis) lens--Cradle to grave analysis. I feel that future processes conceived and developed by life cycle analysis, if implemented well, could strengthen the ethical and humanitarian values that the engineering and business communities should strive toward.

One Solution May Not Fit All - Geographic Challenges and Sustainability

Despite several press releases on sustainability, McKinsey Global Survey on Sustainability reports that many companies are not actively managing sustainability. More than 50 percent of executives consider sustainability "very" or "extremely" important and about 30 percent of executives say their companies actively seek opportunities to invest in sustainability initiatives or embed it in their business practices. Yet, just over 6 percent of executives say that sustainability is a top-three priority on their CEOs' agendas and actively seek to invest in it (heard during LDC 2010).

Of course, there are many challenges--technically and financially--associated with converting processes to sustainable standards or inventing sustainable process. Are these sustainable processes transferable/relevant across the geographic boundaries or do they offer any specific advantages for a particular country? The chemicals from tree-based feedstock may be valuable for the U.S. and some parts of South America but not for other countries such as India (lack of forest) etc. Sugarcane-based fuels (and chemicals) may be a valuable in Brazil and similarly crude oil based processes are advantageous for the Middle East. Anything we do as a chemical engineer to improve the quality of water (especially improving the sea water) will help the Middle East, Asia and African countries significantly.

The point to be noted is if a sustainable process is only relevant to one country, it may offer them a strategic positional advantage but at the same time researchers across the globe may not be involved in solving the problem. There may be secondary processes that use treated/refined feedstock and intermediates that are universal and could engage parties across the globe to solve the technical challenges related to making these processes sustainable. To make such secondary processes economically feasible one has to weigh in the impact of globalization, the differences in capital and labor costs across the globe, acquiring talent, and any artificial barriers introduced/removed by politics.

We all know that primary conversion (converting/extracting naturally occurring crude resource to usable resource) is expensive--be it capturing, mining and converting natural gas/coal to syngas (Coal mine accidents; capital cost in separating oxygen from air to run combustors, oxidizers etc), getting crude from the deep sea (think about the BP spill) or the conversion of solid tree to primary working fuels/chemicals (lignin removal and further conversions). Processes depending on natural resources offer advantages to the countries that own those resources. Technologies for secondary processes are relatively inexpensive or may be available already and are not geography dependent.

Thus, commercialization of secondary processes will make sense in secondary places (natural gas may be less expensive to convert to liquids rather than to transport), where the conversion costs are lower. Geographically mobile secondary processes offer different challenges in making them sustainable, which may require government policies or intervention.

Dr. James Katzer, in his recent keynote at ISCRE-21 was afraid that research, development and deployment (RD&D) are inter-related and R&D may hop geographical boundaries if deployment or demonstration takes place in different regions of the world. He pointed out that with shifts in manufacturing of semiconductor industries to Asia, R&D in that field has moved out of U.S. to those Asian countries. This may be repeated for solar- or wind-based technological solutions but may not occur for processes that have positional advantage. We may have to distinguish between basic research and developmental research. The basic research should take place in any part of the world irrespective of whether developmental research moves to the place of deployment or not. Cutting-edge basic research may be protected by IP and other export control regulations or other agreements.

Sustainability - In its Infancy

I believe the work and solution to sustainability challenges are still in its rudimentary stages. Prof. Brent Shanks lists several technical challenges in this process--the need to convert selectively, highly functionalized wood molecules and to develop hydrothermally stable catalyst and catalytic liquid-solid interfaces in which the liquid phase is commonly aqueous. Many more molecular level modeling techniques need to be developed and validated (many other challenges will be listed in IECR's special edition to ISCRE-21). To tackle this monstrous challenge we may have to adopt a "learning by doing" approach, as pointed out by James Katzer recently. We also need collaborative support from industries and government.

The recent article from TIME (July 5, 2010) alarms me: U.S. investment in R&D remained constant since the mid-1980s at 2.7% of total GDP with the federal share constantly declining. Asian nations like Japan and South Korea have rapidly increased their investments. China's investments in R&D grew more than 20% between 1996 and 2007, compared with less than 6% annual growth in the U.S.

Equally important is how we need to take sustainability initiatives in other aspects of life such as family values and culture so that it can be transferred to our future generations. My mind immediately wavered to a recent talk I had heard in one of the churches here on sustaining religious faith. It is clear that like the universe, the word sustainability is expanding in scope.

I will probably have to give serious thought to using my bike to get to the park next time instead of driving my car. With this new motivation, I sign off now.

How do you view Sustainability in relation to Chemical Engineering?

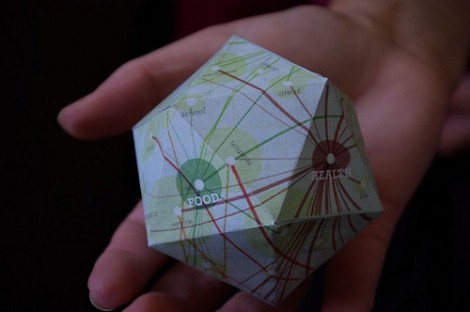

image: hand holding world-densitydesign

image: Fort Patrick Henry Lake-Dacoshi

image: green chemistry-maveric2003

image ten little piggies-Brandon Doran

image: sustainability tree-xotoko

image: windmills-Monica's Dad

Related articles by Zemanta

- Can Sustainable Farming Really Feed Us? (energybulletin.net)

- Chemical engineering progress (chem-eng-net.com)

Comments

You make a lot of good points. Sustainability means different things to different people - what they can live with and can't live without and the comfort level they are willing to sacrifice differs between people. Sustainability has become a buzzword of sorts and has seeped into conversations that don't pertain to the environment at all. Very interesting! Thanks!

Thanks Elizabeth. You have condensed my thoughts in a couple of sentences in your feedback /comments. Infact they were the very seed for writing this blog. These days 'water' and 'medicine' have joined the sustainability ranks. I heard that in DuPont, even employee safety comes under sustainability.

UN defintion of Sustainability: ”Sustainable Development is development that meets the needs of the present without compromising the ability of future generations to meet their own needs" No wonder why water and medicine can be included !!

Agreed, sustainability is a very broad concept. I think that makes it hard for some people to get their heads around. It seems like when you think about an aspect or learn something related to it, more questions are opened than closed. And sometimes it requires turning common practices on their head. For example your reference to Cradle to Grave analysis, there are many improvements that can be made to products to reduce their waste in manufacture, or toxicity, or durability/cost effectiveness. But what if you made a product that could have another use when its original was completed. There is a snack food company that is working on developing a compostable bag. After you are done eating the chips the bag can be composted and become fertilizer for growing more snack food. Cradle to Cradle, even more sustainable. Also, I liked your point that many advancements are going to be local (though I don't think that means that there won't be universal concepts). Many solutions are also going to be low-tech and were figured out long time ago, but have since been forgotten. In many earthquake prone areas the indigenous people built structures with local materials that were resistant to earthquakes. But as others moved in , they wanted to build structures from where they came from with materials they were familiar with. But they were ill suited for the locality. Same is true with energy consumption of buildings, before A/C we were able to make buildings that preserved the cool of night and had good air flow. Now everything is a sealed box. As for Che, I think it is the best suited discipline to help with many of these issues. We can help get the most of every resource we use, develop new, better resources that will not tax the environment as much, and develop new materials that need few resources. For such a diverse problem, this is a diverse field well educated to solve it.

Well said Robert ! I think some aspects of the sustainability problems can be solved by the traditional chemical engineering approach and for some others out of the box thinking, like cradle to cradle etc approach could help. The localized solution is going to help a lot in this area. I will be very eagerly following the solution to the main crux of the problem---- in breaking large bio molecules to useful products. I think biological science based chemical engineering currriculum will help the future students to prepare for this challenge.

This is a great post which I very much enjoyed reading. I hope to read more like this. I agree that solutions and innovative process changes will dependent largely on the regional resources which are available when designing/optimizing sustainable process, and liked how you broke that out. Ultimately it is our collective value systems that will steer the rate of sustainable innovation, but think that the U.S will have a long term R&D advantage: diversity = innovation....